Prima Additive for the heat exchanger industry

Find out what we do for the heat exchanger industry

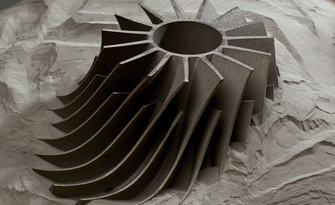

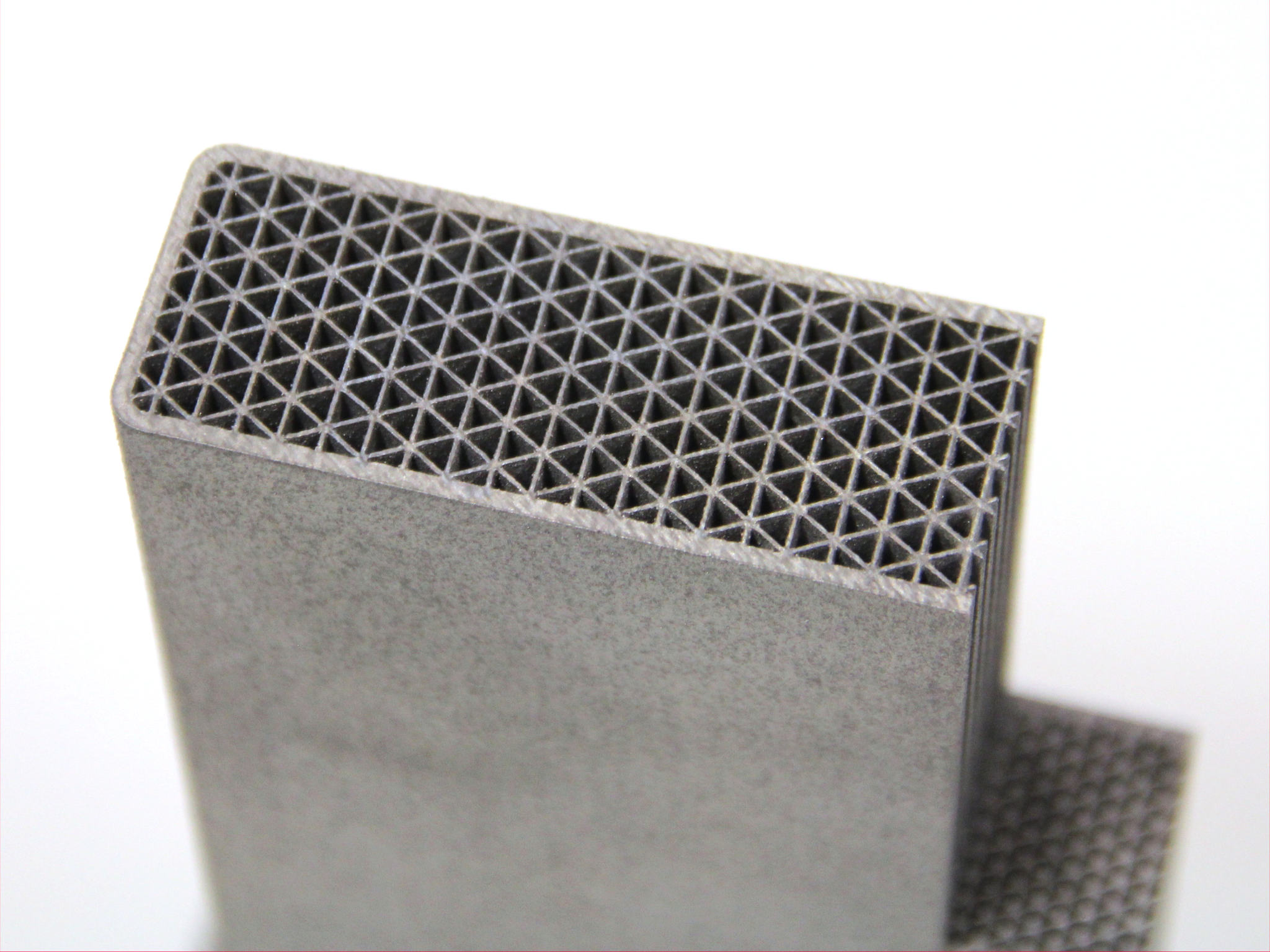

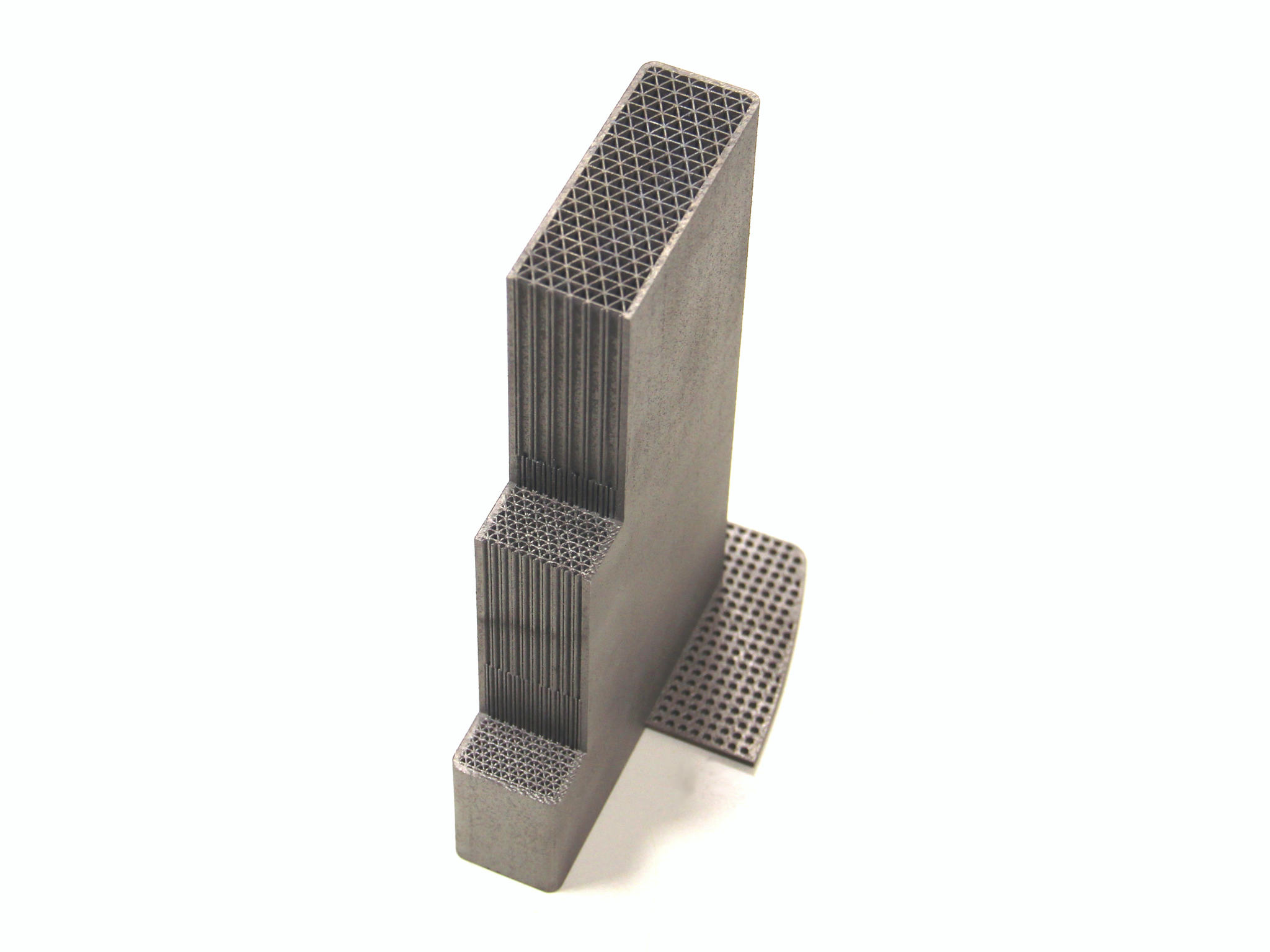

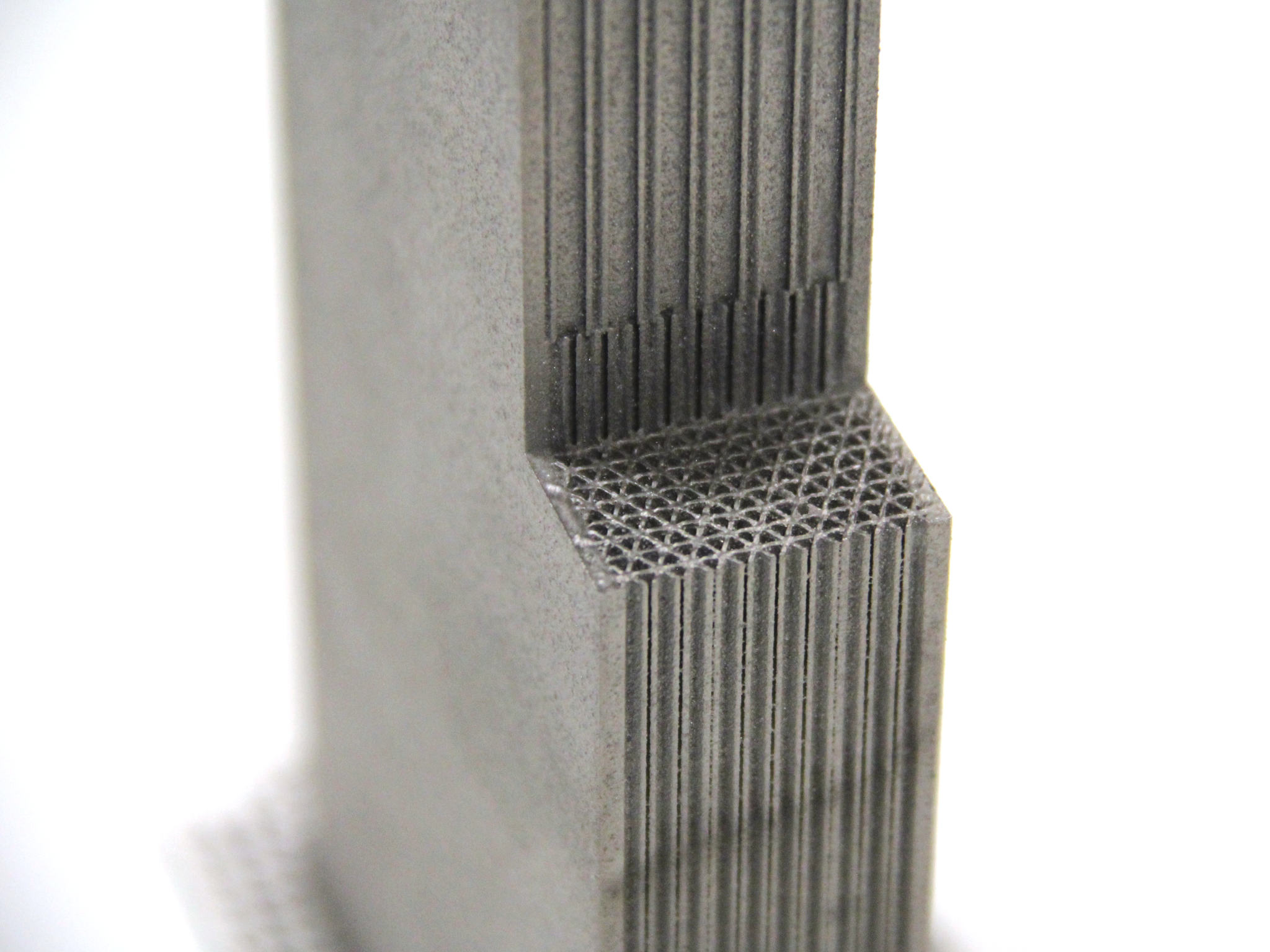

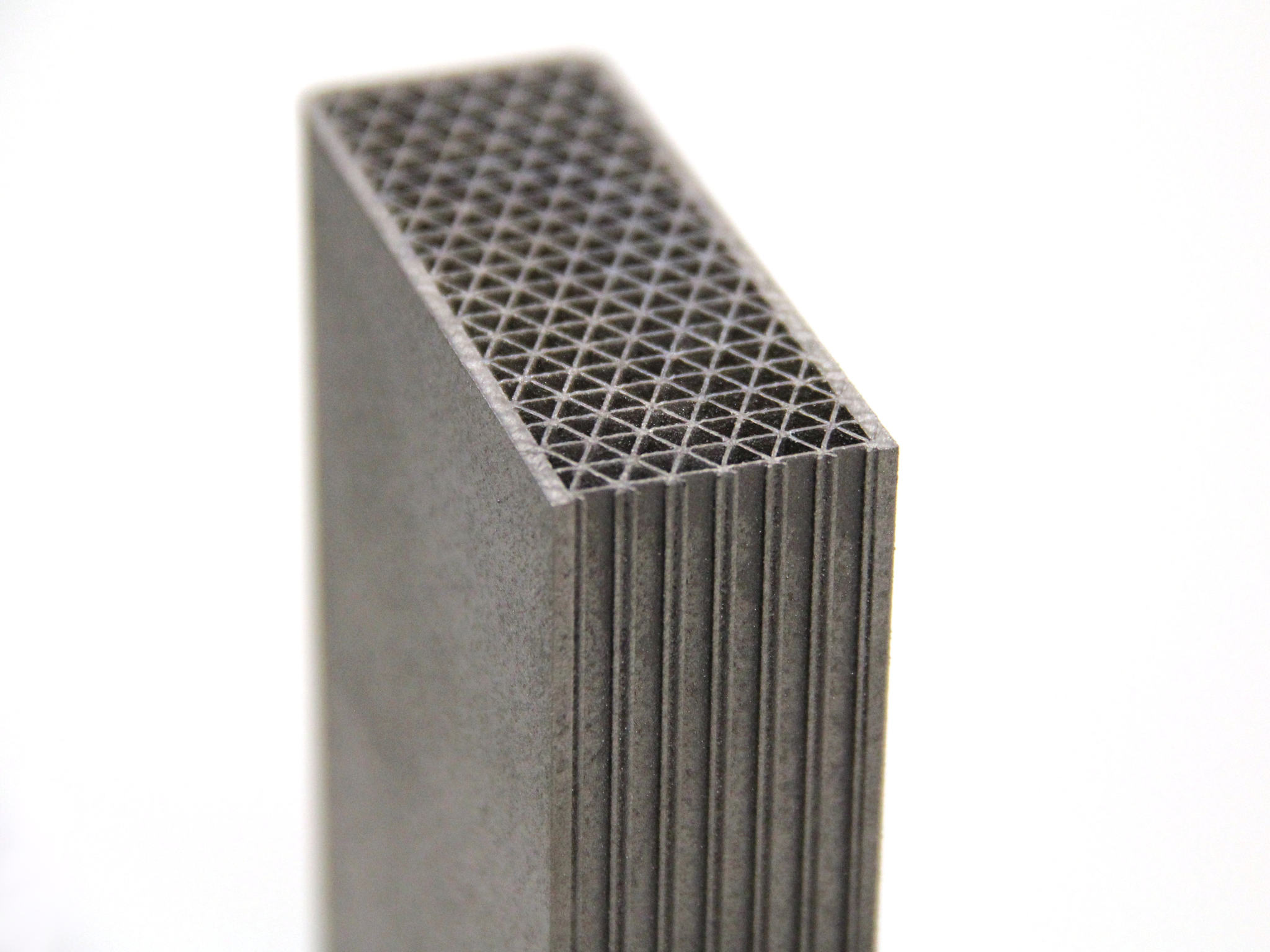

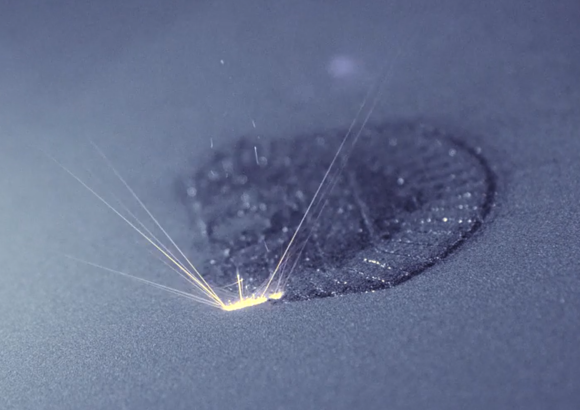

In the heat exchanger industry, optimizing performance while reducing weight and improving thermal efficiency is critical. With Powder Bed Fusion (PBF) technology from Prima Additive, you can move from CAD directly to production, enabling the creation of intricate, previously unattainable geometries. This is particularly valuable in industries requiring high-efficiency heat exchangers, as complex internal structures can be consolidated into a single part, eliminating the need for assembly and improving overall thermal conductivity.

Using PBF, heat exchangers with thin walls and complex passages can be produced, enhancing heat transfer while reducing size and weight. This flexibility in design, combined with the ability to work with a wide range of metals, allows for the optimization of thermal performance and mechanical properties, ideal for applications in energy generation and industrial cooling systems.

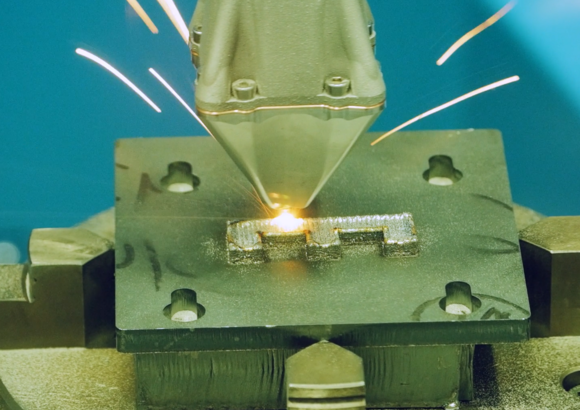

For added durability, Direct Energy Deposition (DED) offers precision repair and coating capabilities. This allows heat exchanger components to be coated with materials that resist corrosion and wear, extending their lifespan even in the most demanding environments. By applying high-performance coatings or repairing worn sections, DED ensures that heat exchangers continue to operate efficiently without the need for full replacements.

Solutions

Find your ideal solution

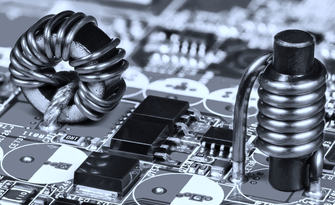

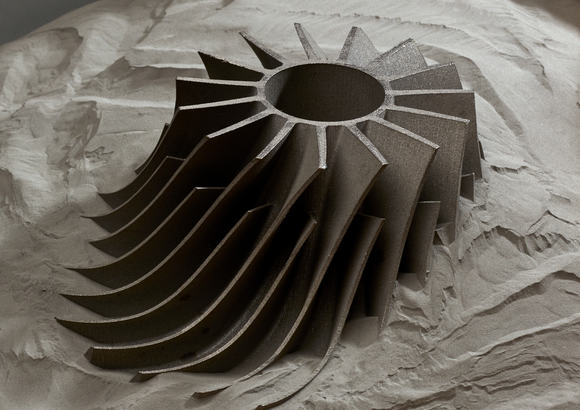

We are at your service to help you take full advantage of the shape flexibility made possible through metal additive manufacturing. We will support you in redesigning your heat exchangers and in the choice of materials.

Thanks to our solutions, you can reduce the time between design, prototyping and production of the final part, giving you the opportunity to experiment with new shapes and digitally customize each part according to its use.

Main Applications of Metal Additive Manufacturing in the Heat Exchangers Sector

Behind every innovation there is a Prima Additive machine

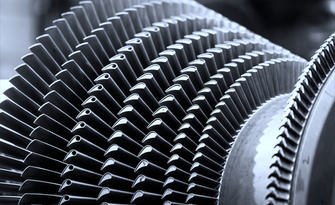

- Ultra-efficient heat exchangers for aerospace applications, significantly reducing weight and improving fuel efficiency.

- Customized heat exchangers for electric vehicle charging stations, optimizing cooling performance to enhance charging speed and safety.

- High-performance cooling solutions for industrial processes, designed to minimize energy consumption and maximize heat recovery.