Aluminum alloys for PBF

Materials for Powder Bed Fusion

All the lightness of working with aluminum.

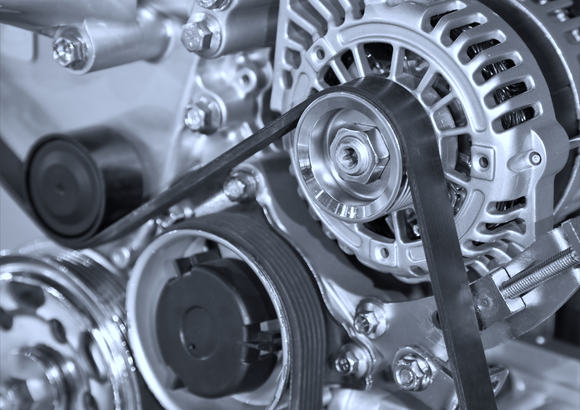

Diving into the world of aluminum powders, powder bed fusion technology for metal additive manufacturing reveals an evolving landscape where the limits of engineering and design are constantly pushed further. This journey into advanced manufacturing technologies shows us a future where innovative materials and processes redefine what's possible, blending the realms of aluminum alloys and their powdered forms with the precision and versatility of powder bed fusion in metal additive manufacturing. This integration not only expands the boundaries of what we can create but also how we think about the fabrication of components across industries.

Aluminum, known for its lightweight yet strong characteristics, finds a new dimension of application when processed through powder bed fusion technology. This advanced method of metal additive manufacturing enables the creation of parts that were once deemed impossible.

Advantages of Working with Aluminum Alloys via Powder Bed Fusion

Enhanced Material Properties

Processing aluminum alloys with laser powder bed fusion enhances their mechanical properties such as strength, hardness, and thermal conductivity. It also improves electrical conductivity and corrosion resistance, making these materials ideal for high-performance applications.

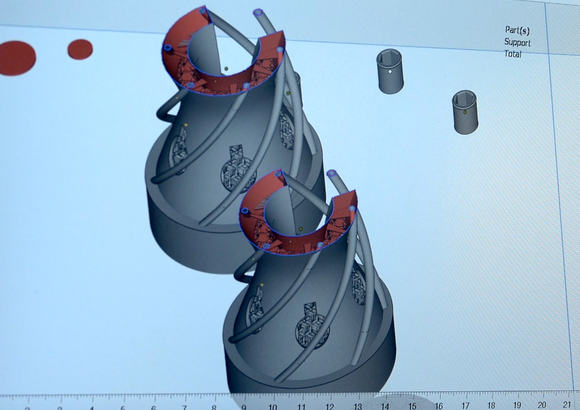

Complex Geometries and Detailed Designs

The technology allows for the production of complex shapes and intricate details with high precision, which are difficult to achieve through traditional manufacturing methods.

Efficiency and Sustainability

Powder bed fusion offers reduced material waste and energy consumption compared to conventional manufacturing processes, aligning with the goals of sustainability and efficiency in production.

Main Aluminum Alloys Processable with Prima Additive by Sodick Systems

Prima Additive by Sodick's machines are capable of processing a range of aluminum alloys, including but not limited to:

- AlSi10Mg: Known for its good strength, hardness, and thermal properties, making it suitable for a wide range of applications.

Beyond the Basics

While AlSi10Mg is a popular choice, it's important to note that this is just a starting point. Prima Additive by Sodick's machines are designed with open parameters, allowing them to work with any type of material made by any manufacturer. This flexibility ensures that users are not limited to specific alloys and can explore a wider range of materials to find the one that best fits their application needs.

By embracing the capabilities of powder bed fusion and the versatility of aluminum alloys, Prima Additive by Sodick is at the forefront of the development of metal additive manufacturing. The materials mentioned are indicative of the most commonly used alloys in metal additive manufacturing. However, we have experience on a wide range of materials and can provide you with support in developing the alloy that best suits your needs, to allow you to make the most of this technology.

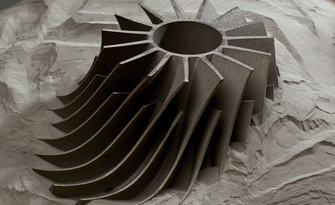

Application examples

| Industry |

Aerospace |

|---|---|

| Build time |

28 hours for 1 unit |

| Layer thickness |

30 μm |

| Material |

AISi10Mg |

| Part dimension (X-Y-Z) |

107 x 153 x 155 mm |

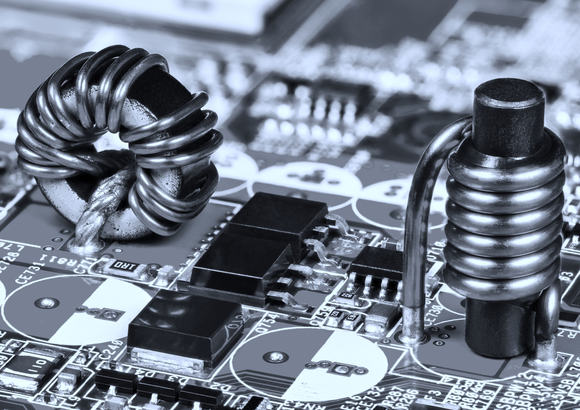

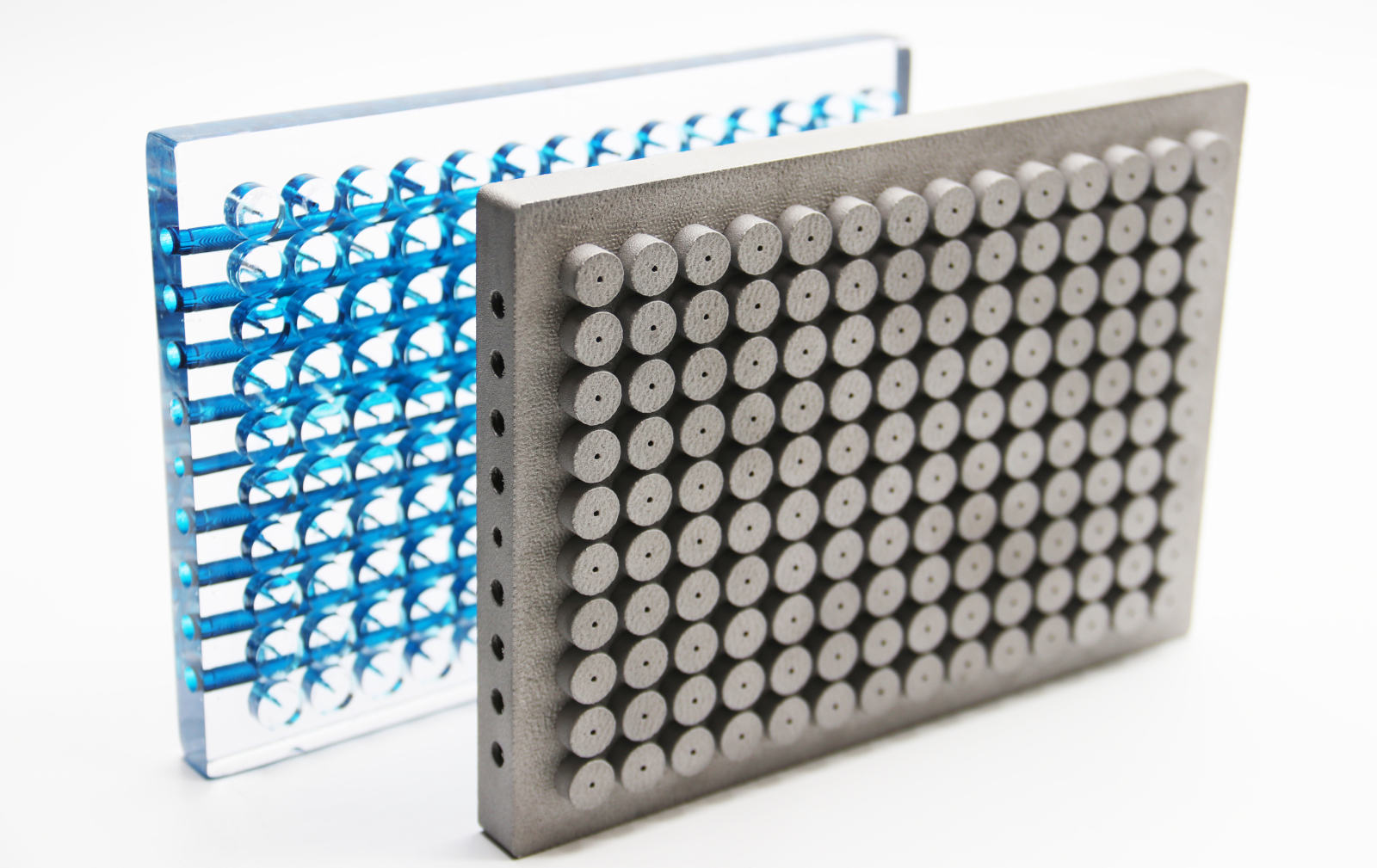

| Industry |

Electronics |

| Build time |

20 hours for 1 unit |

| Layer thickness |

30 μm |

| Material |

AISi10Mg |

| Part dimension (X-Y-Z) |

142 x 102 x 15 mm |

Areas of application

Did you know that aluminium alloys are widely used in these sectors?

Need to make parts using a different material?

We are at your service to research and produce new materials suitable for additive manufacturing to meet your specific needs.

We will evaluate your business case and together develop the best material for your application.

Take advantage of our services

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

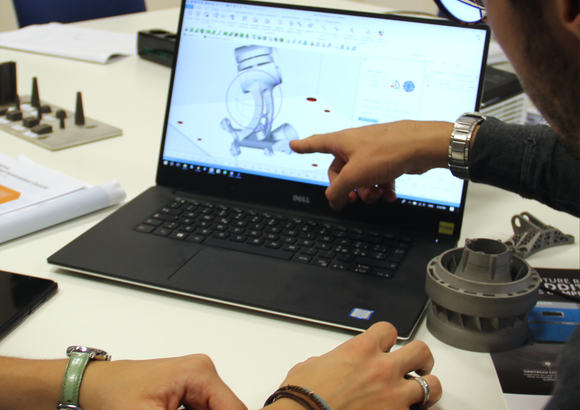

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Here are our solutions for processing Aluminium alloys for PBF

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

300 Family

Powder Bed Fusion Technology