Advantages

Advantages of metal additive manufacturing

Discover how Additive Manufacturing can revolutionize your business.

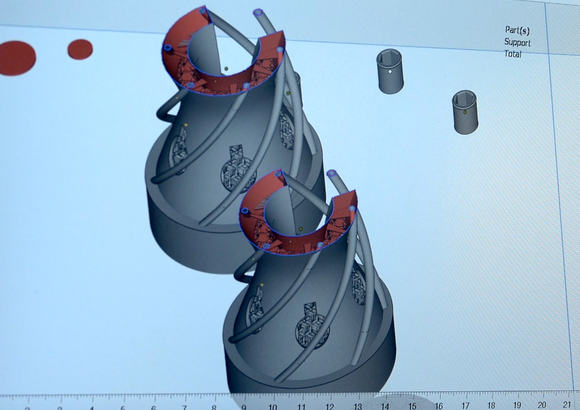

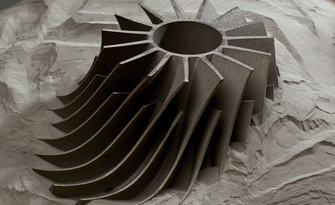

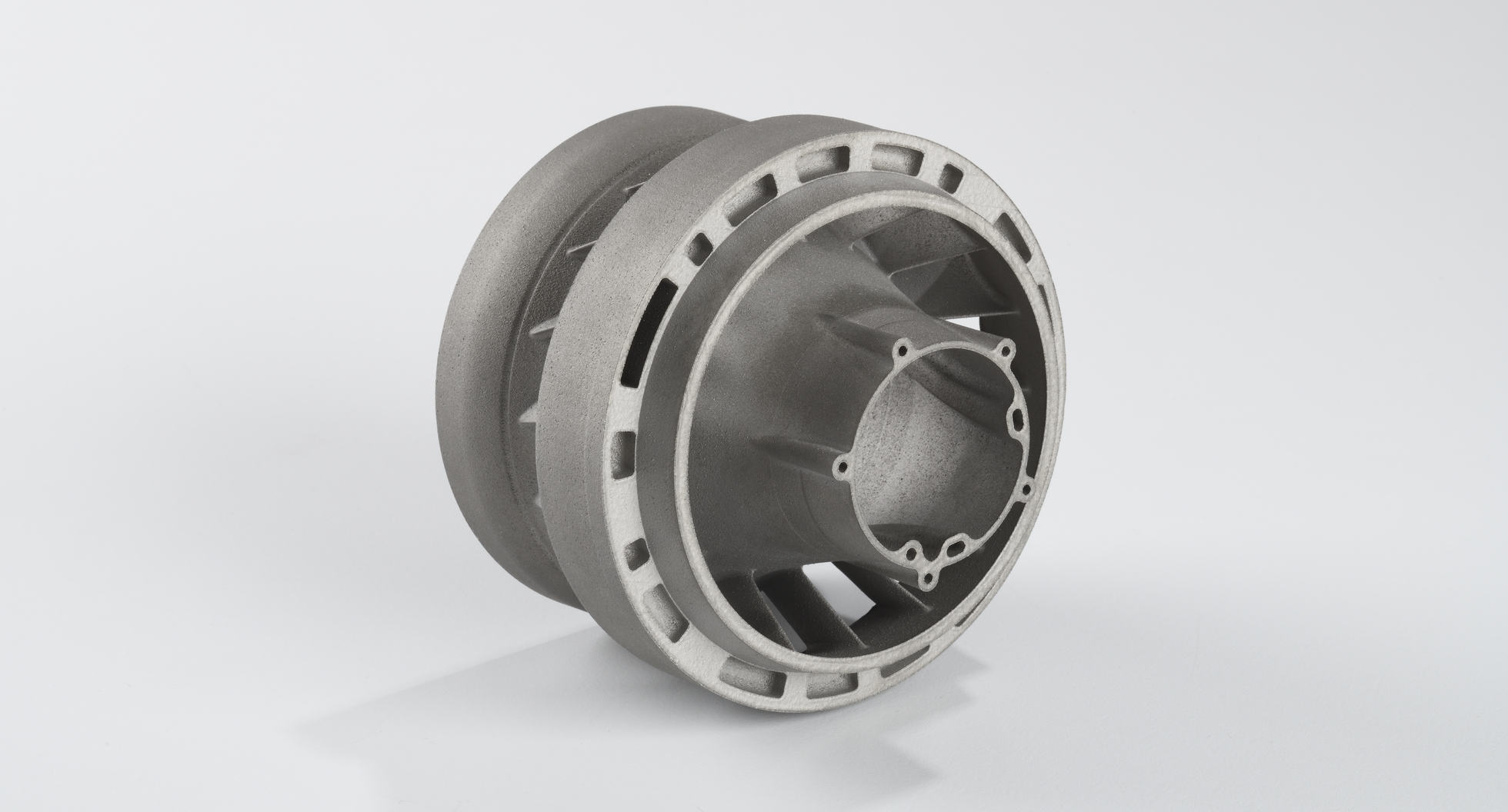

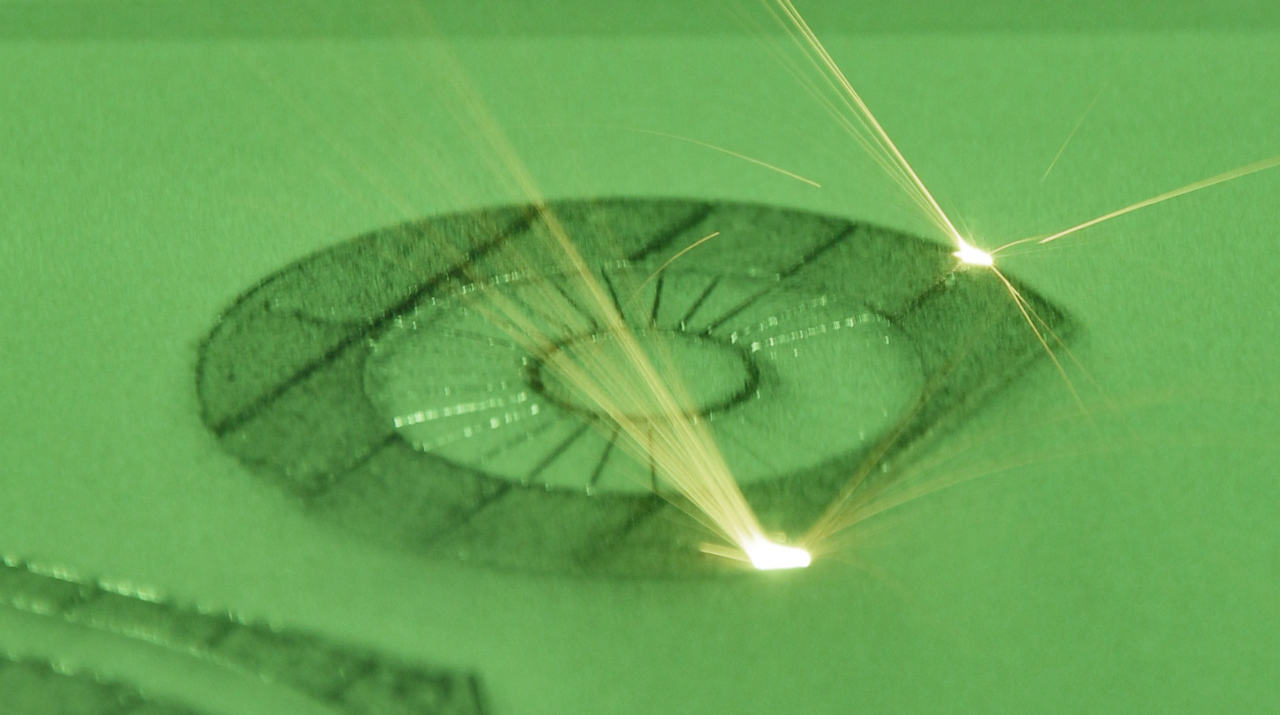

Design freedom

Metal additive manufacturing, thanks to its layer-by-layer creation process, first and foremost allows you design freedom unthinkable with traditional metalworking technologies. By 3D printing a component instead of machining it, you can create complex geometries with unmatched precision and level of detail.

In this way, you can redesign components with a shape that is functional to their use rather than a shape that suits the production technology. What's more, you can consolidate multiple parts into one piece, resulting in a better-performing design while eliminating assembly time and related issues.

With additive manufacturing, you can also make parts with very complex internal channels, which ensure optimal cooling of the components.

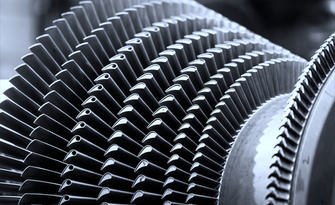

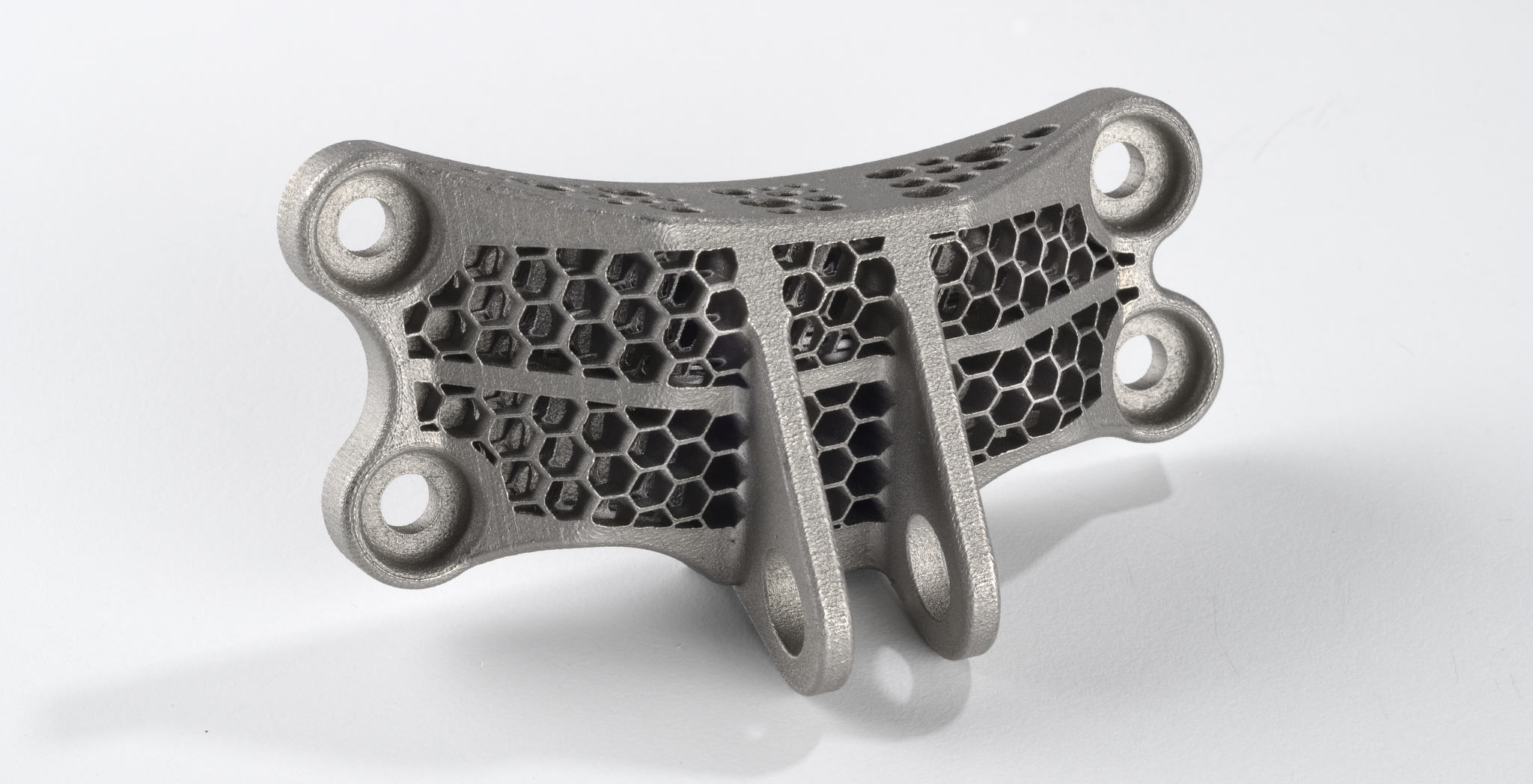

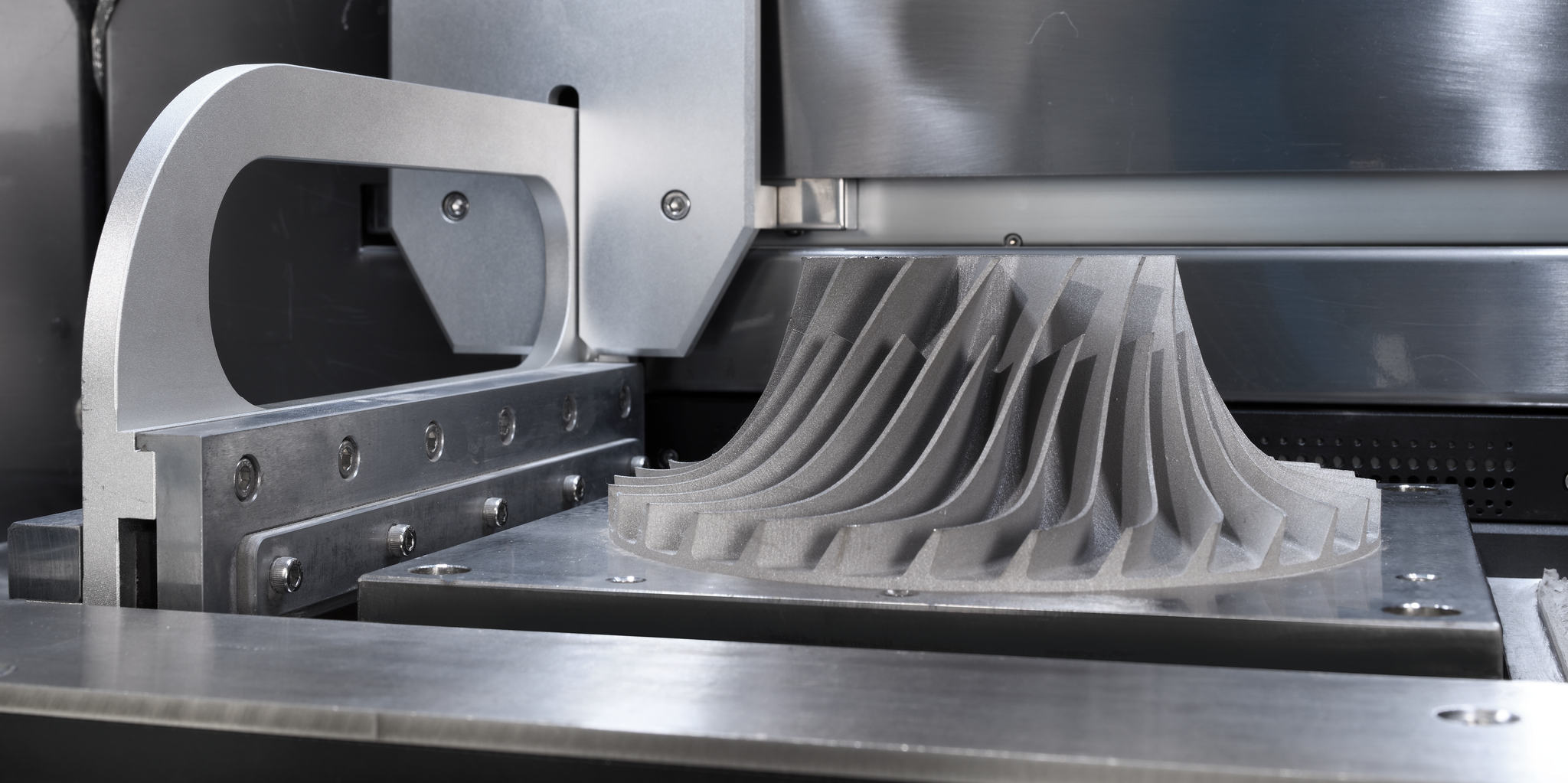

Lighter parts

Since component design is optimised according to its actual use, you can create lighter parts by emptying full parts into lattice structures, creating organic, fluid shapes where previously there were square, solid parts.

Think of the advantages that lighter parts can bring to sectors such as aerospace or motorsport: greater competitiveness, better performance in cars, reduced fuel consumption in aircraft, etc.

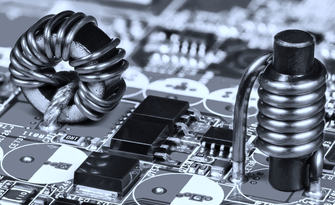

Finest mechanical characteristics

The mechanical characteristics in terms of porosity of the material, high-temperature resistance, and resistance to stress and fracture are comparable to, if not better than, parts produced with traditional or cast technologies.

Rapid prototyping

An object can be designed, printed, and tested much more quickly and accurately, eliminating several steps in the product development process, with a drastic reduction in errors, thanks to a system that controls the whole production process layer by layer.

In this way, the time from idea to implementation is shortened, prototyping time is reduced, enabling you both to go to market faster and to test more variants and customizations. So you can provide your customers with better and more reliable parts, improving the entire product development process.

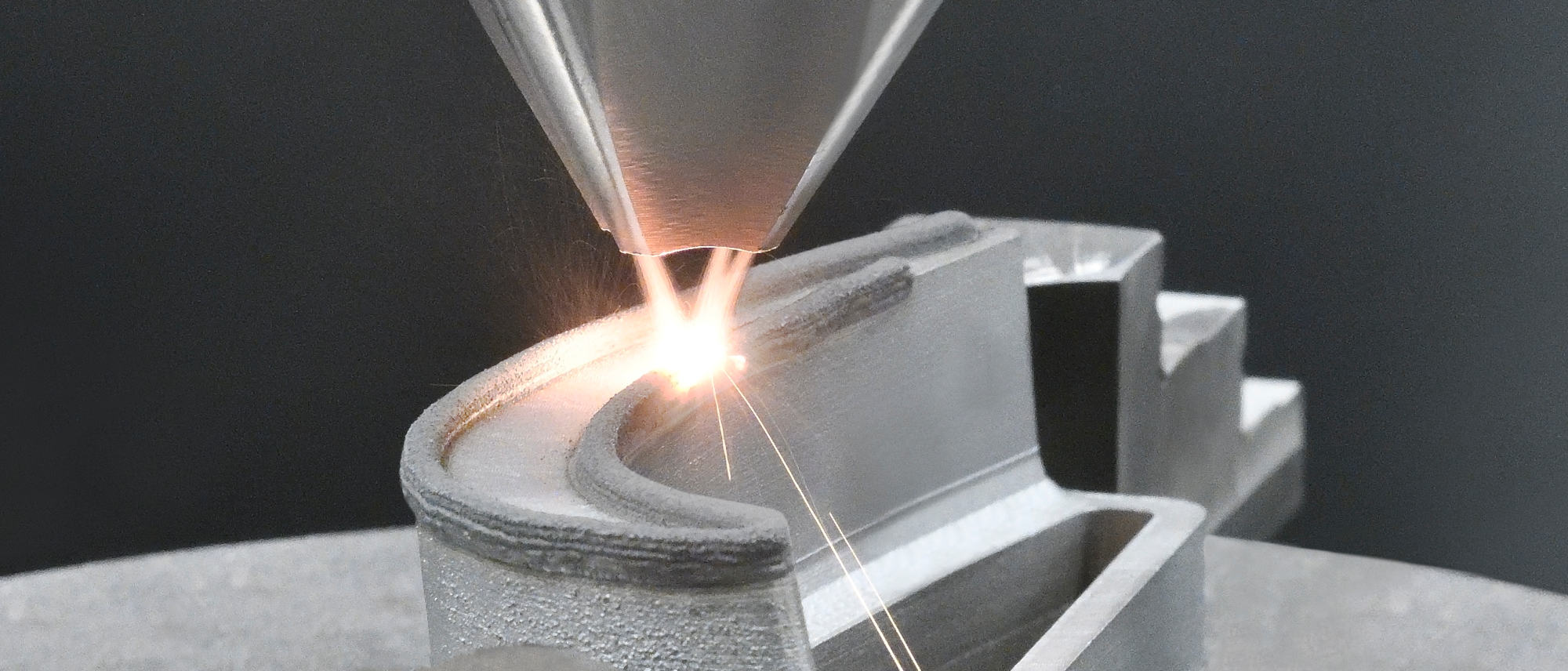

Repair and customization of components

Not just building parts from scratch: Prima Additive by Sodick’s Direct Energy Deposition solutions also allow you to repair metal parts, as well as coat them with other metal or add customised parts to existing parts. In this way, instead of creating new components, you can reuse what you have, making your business “greener” and more sustainable and, above all, save money.

Reducing waste

With the layer-by-layer powder fusion process, only the material needed to produce the object is used. The metal powder used in the production process and that is not melted can be recycled and used later. This drastically reduces production waste, which is a major issue with traditional machining technologies.

More product control

The infinite possibilities offered by additive manufacturing allow you to make any part that can fit within the working area of the machine. In so doing you can produce parts that were previously made by different suppliers, or make third-party parts for the most varied of sectors.

In addition, additive manufacturing revolutionizes the supply chain: it is, therefore, possible to produce parts on-demand, preventing large stocks of spare parts being kept in a warehouse, but producing only what is needed, when it is needed, avoiding long waits and transport costs.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.