Prima Additive for the automotive sector

Find out what we do for the automotive sector

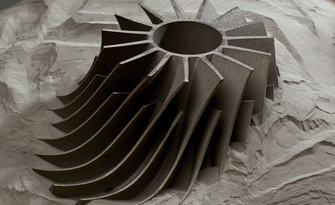

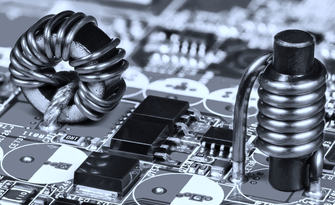

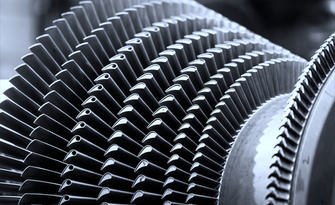

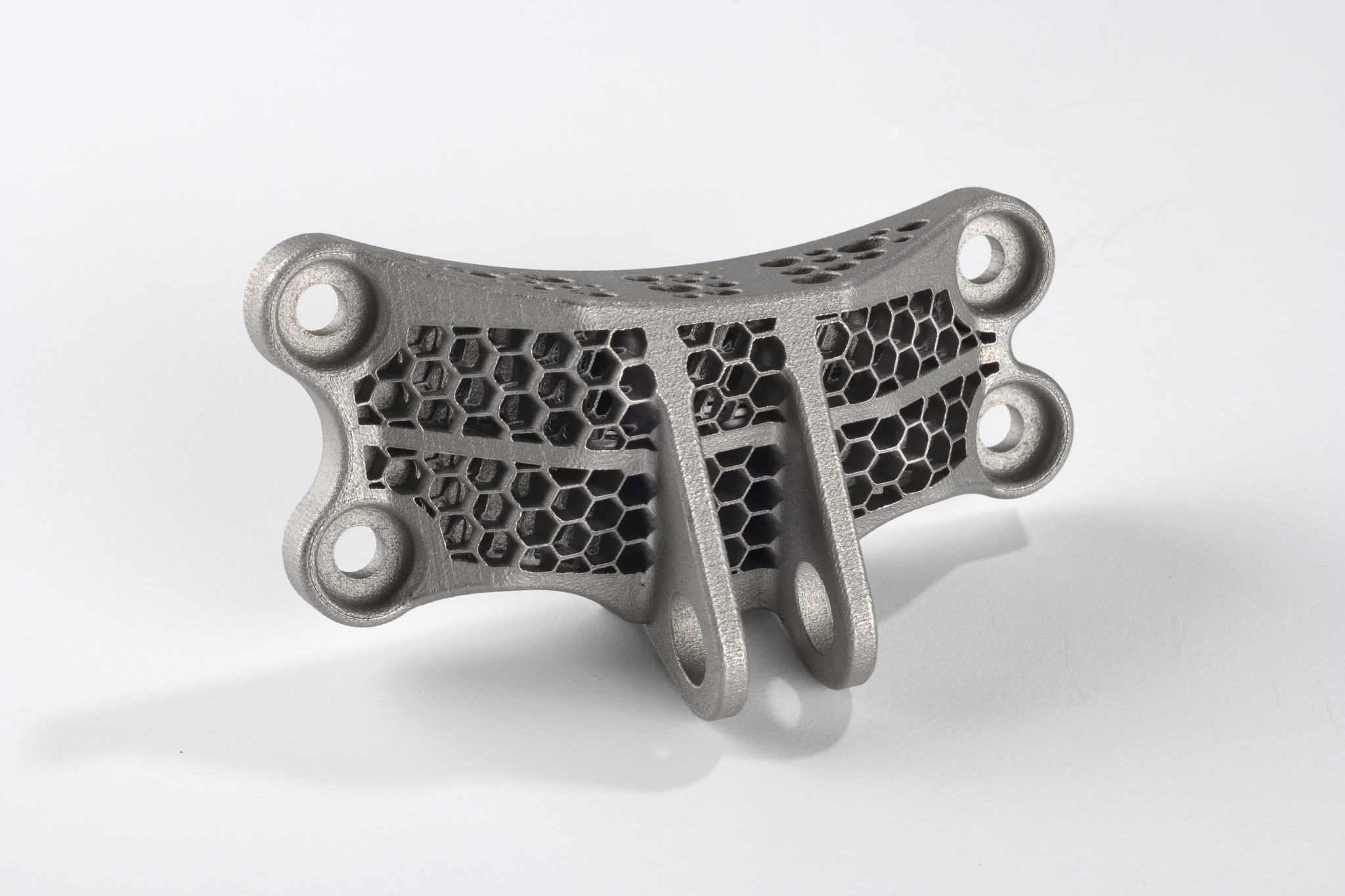

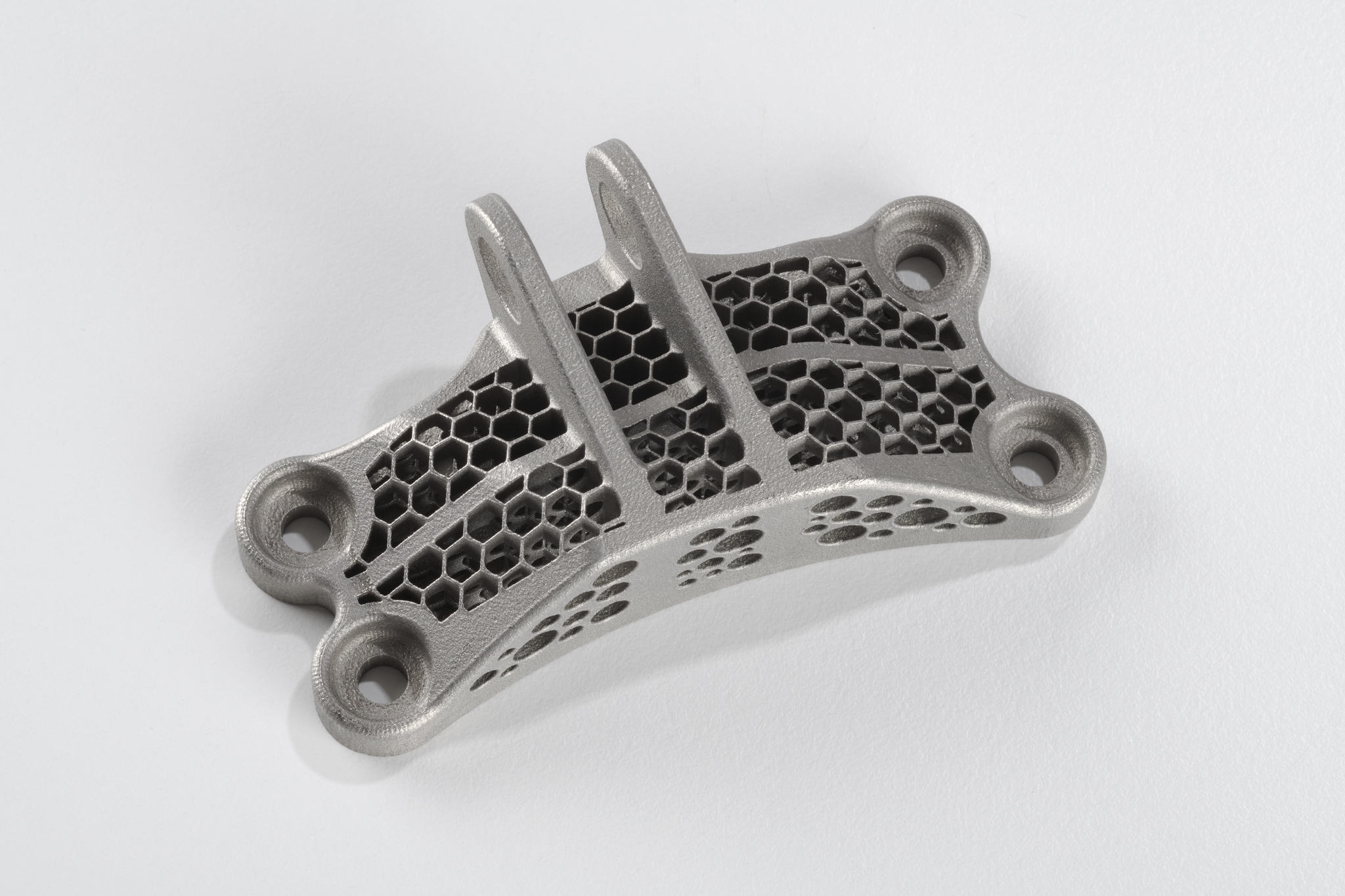

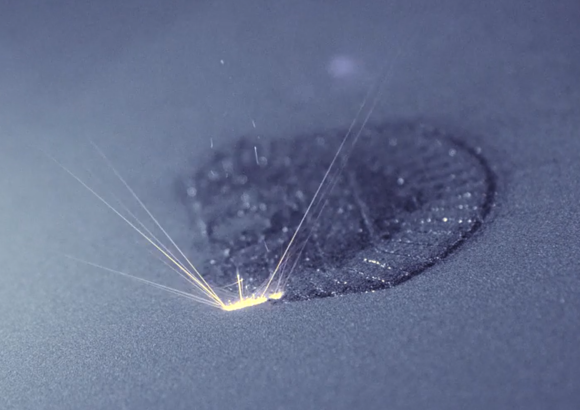

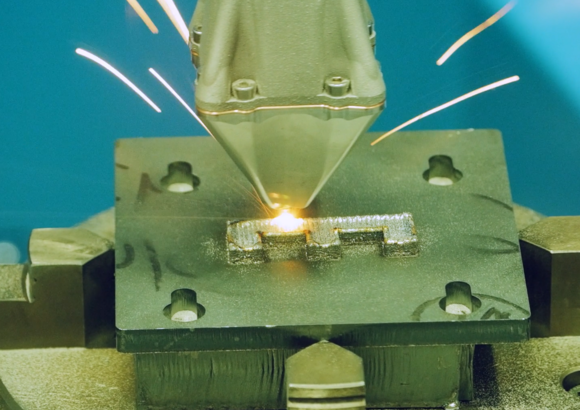

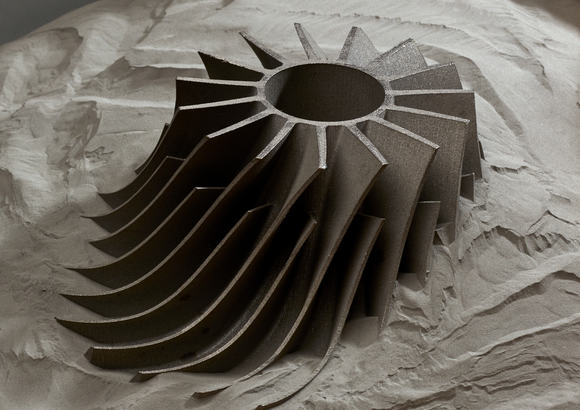

At Prima Additive, we specialize in metal additive manufacturing (AM) solutions designed specifically for the automotive industry. Our advanced technologies, including Powder Bed Fusion (PBF) and Direct Energy Deposition (DED), offer unmatched precision and flexibility, enabling the production of lightweight, complex automotive components that meet the strict performance and safety standards required by the sector.

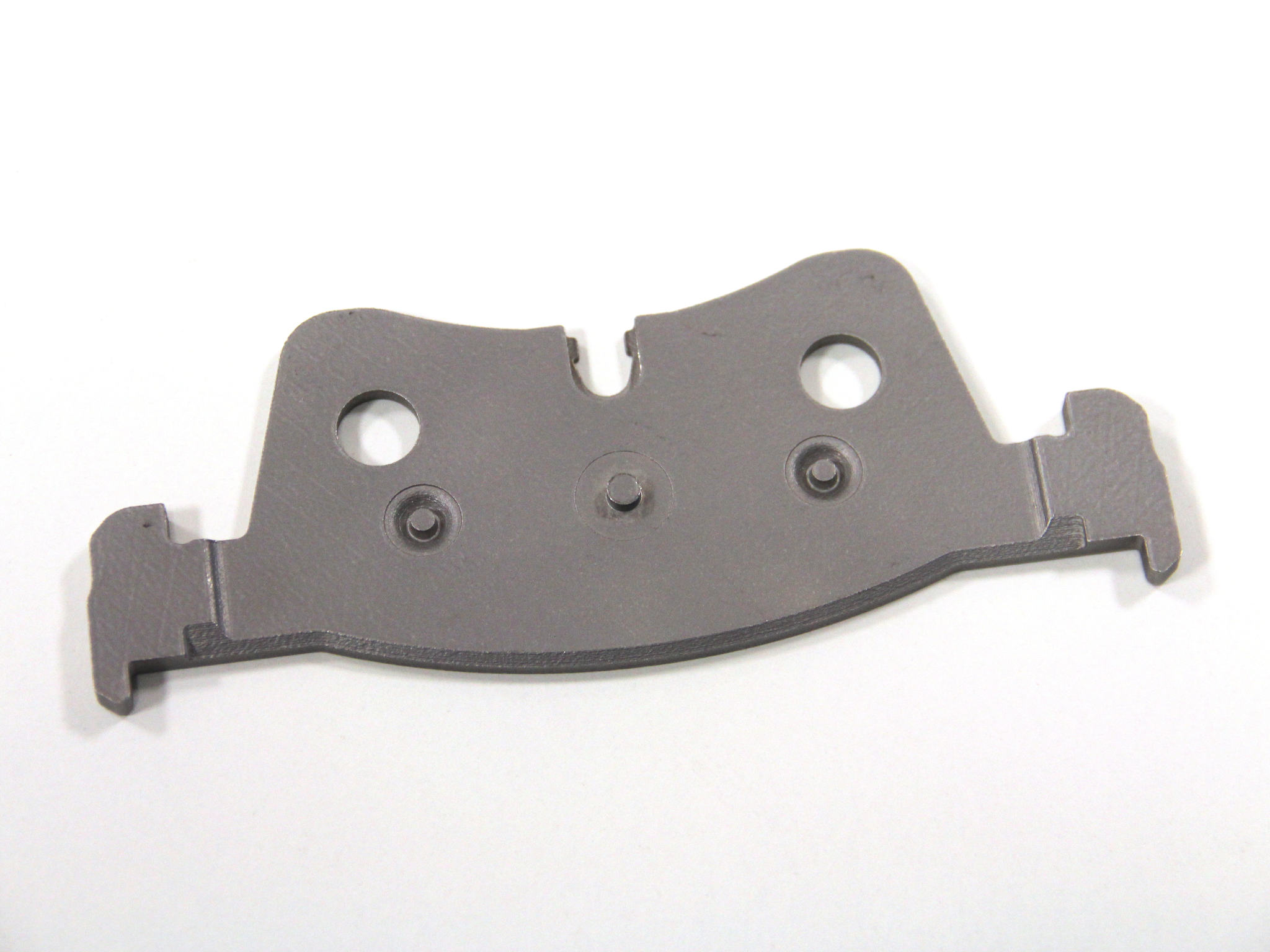

A key innovation is our Rapid Coating (RC) process, a high-speed laser cladding technology that quickly applies wear-resistant coatings using materials such as steel and TiC titanium carbide. By partially melting the substrate and melting most of the powder in-flight, Rapid Coating allows for faster production with excellent surface quality. This is particularly important for the automotive industry, where coated brake discs help reduce particulate emissions, meeting regulations like the Euro 7 standard. With Prima Additive's automated IANUS robotic cell, we provide a highly efficient, 24/7 production process, making it an ideal solution for large-scale, high-volume automotive manufacturing.

Our PBF technology is ideal for producing intricate geometries such as internal cooling channels in engine components, which improve the thermal efficiency of electric motors. DED, on the other hand, is perfect for repairing or adding material to existing parts, allowing manufacturers to enhance and customize components post-production. Both technologies offer significant advantages in terms of speed and material optimization, reducing lead times and costs.

At Prima Additive, we don’t just provide cutting-edge technology: we offer turnkey, fully automated solutions tailored to integrate seamlessly into automotive production lines. With our deep expertise in metal AM and proven success in working with leading automakers, we deliver scalable, customizable manufacturing systems that enable automotive manufacturers to achieve greater efficiency, performance, and sustainability.

SOLUTIONS

Find your ideal solution

We will support you in the process of identifying components that can be made with additive manufacturing and their redesign, as well as in choosing the most suitable materials for your application. We are at your service to help you take full advantage of the shape flexibility made possible by additive manufacturing for the automotive industry.

The speed and ease of use of our machines also means that you can move quickly from design to manufacture, allowing you to modify and customize your parts as required, giving you unmatched flexibility.

Main Applications of Metal Additive Manufacturing in the Automotive Industry

Behind every innovation there is a Prima Additive machine

- Complex cooling systems for electric vehicle batteries, enhancing performance and longevity.

- Lightweight chassis components that maintain structural integrity while improving fuel efficiency.

- Customizable interior components for luxury vehicles, allowing for personalized aesthetics and ergonomics.

- Rapid Coating: High-speed cladding for coating brake discs to reduce pollution emissions from braking systems