Print Sharp 150

OPEN PARAMETERS

User-customisable for research and development of new materials.

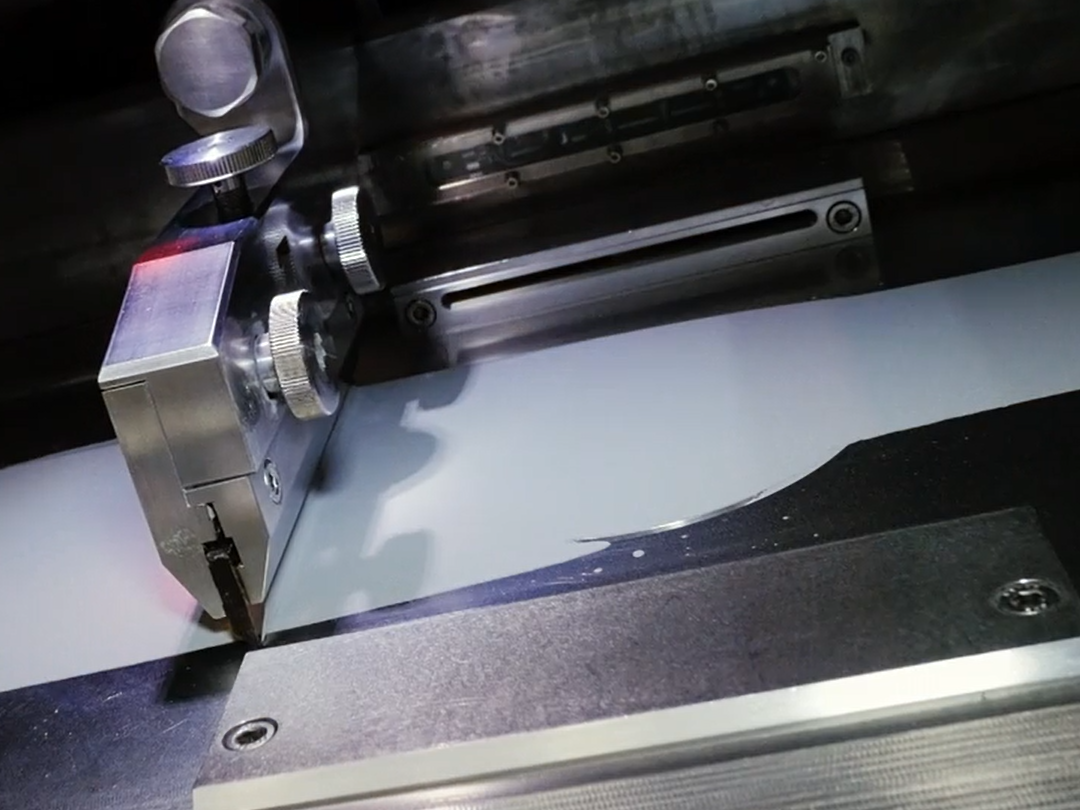

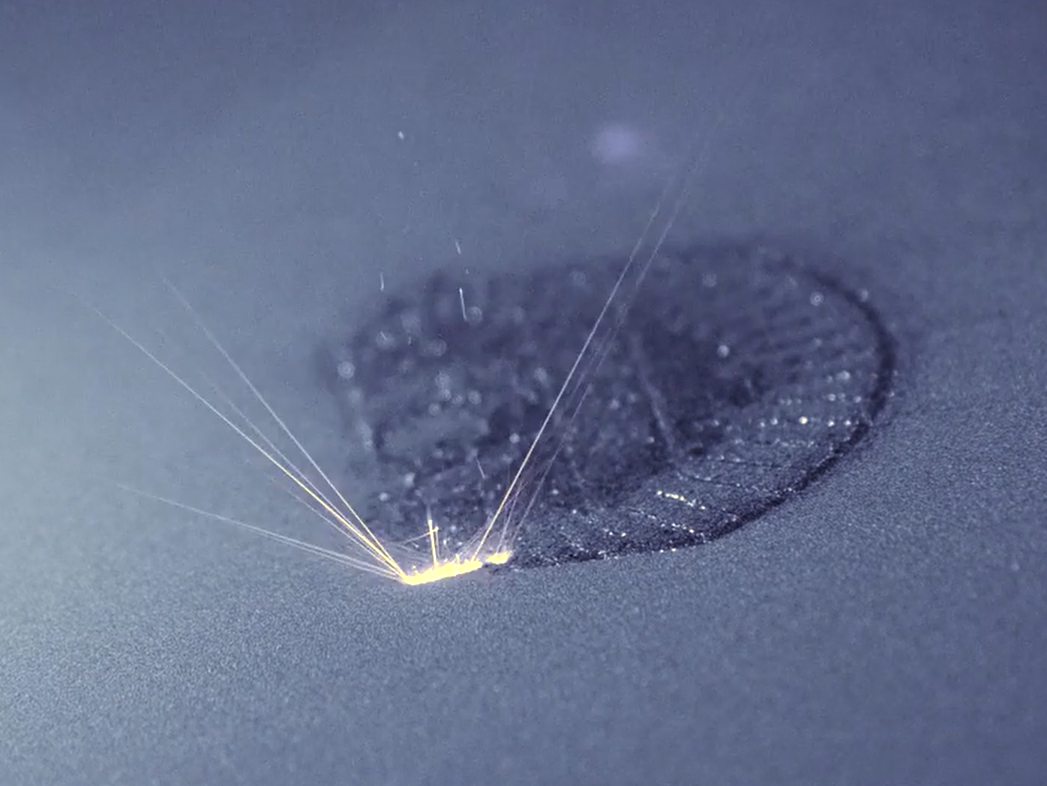

ALL UNDER CONTROL

Control systems analyse any defects in the metal powder layer in real time.

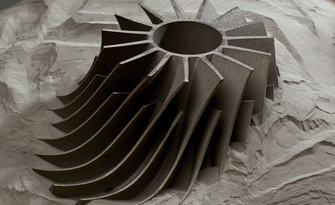

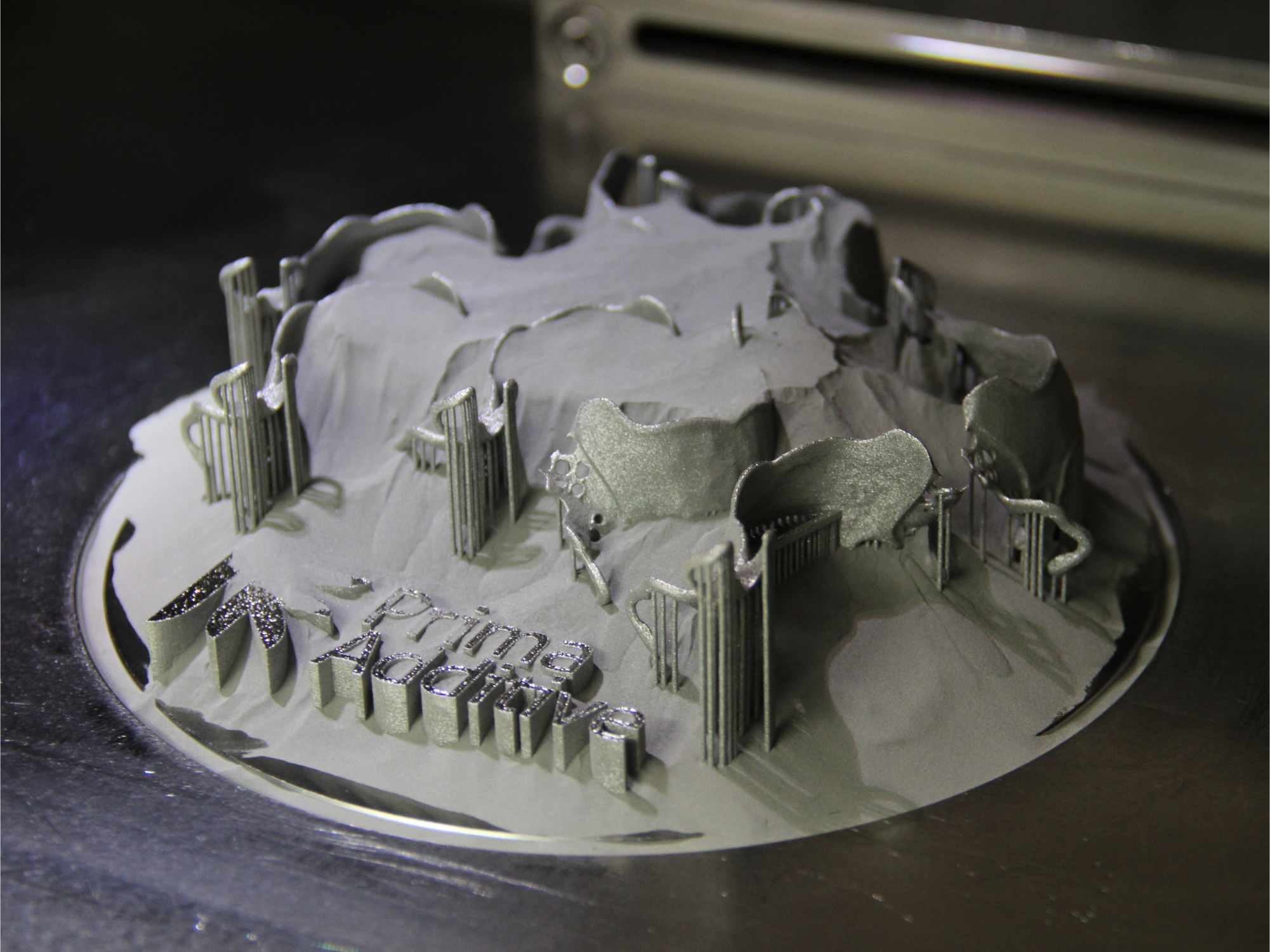

The Print Sharp 150 Powder Bed Fusion machine is an innovative open-configuration powder bed additive system consisting of a cylindrical working area, a preheating system, real-time monitoring of process parameters, and laser spot. A compact additive manufacturing machine with a building volume of Ø150mm and H = 160mm for manufacturing small components.

The system has optimized gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components.

With the ability to customize process parameters, Print Sharp 150 is also ideal for those looking for a machine with which to research new materials.

To reduce the waste of materials, especially when carrying out research on new alloys or processing precious metals, it is possible to install a plate reduction to narrow the area of both the building cylinder and the powder feeding cylinder, bringing the building area to a customized size according to needs, reaching up to a minimum of Ø 30 mm (H = 80 mm). The reduction kit is removable, thus allowing you to use the entire work area or the reduced one depending on application needs.

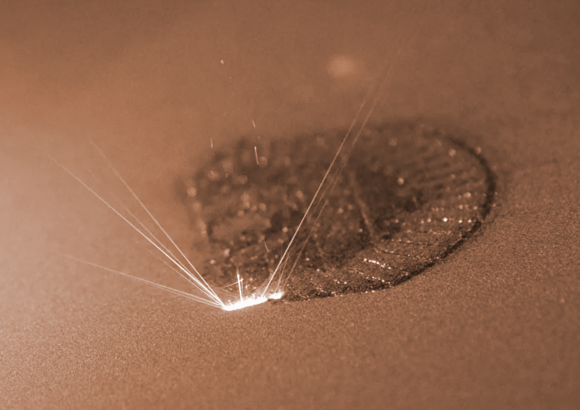

Print Sharp 150 is equipped with a 300W single mode IR fiber laser source. The laser source is air-cooled, so no external unit cooler is required.

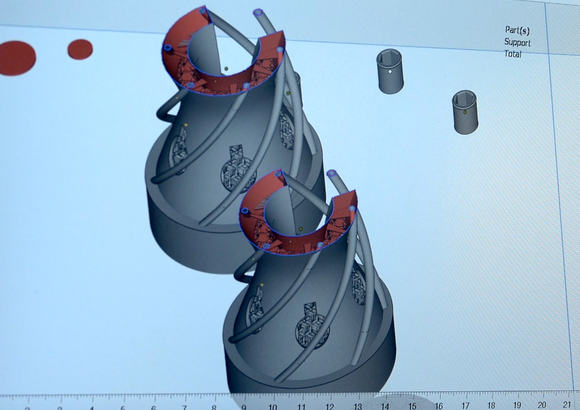

A single line width of 0.1mm and a minimum layer thickness of 0.02mm can be achieved for high precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

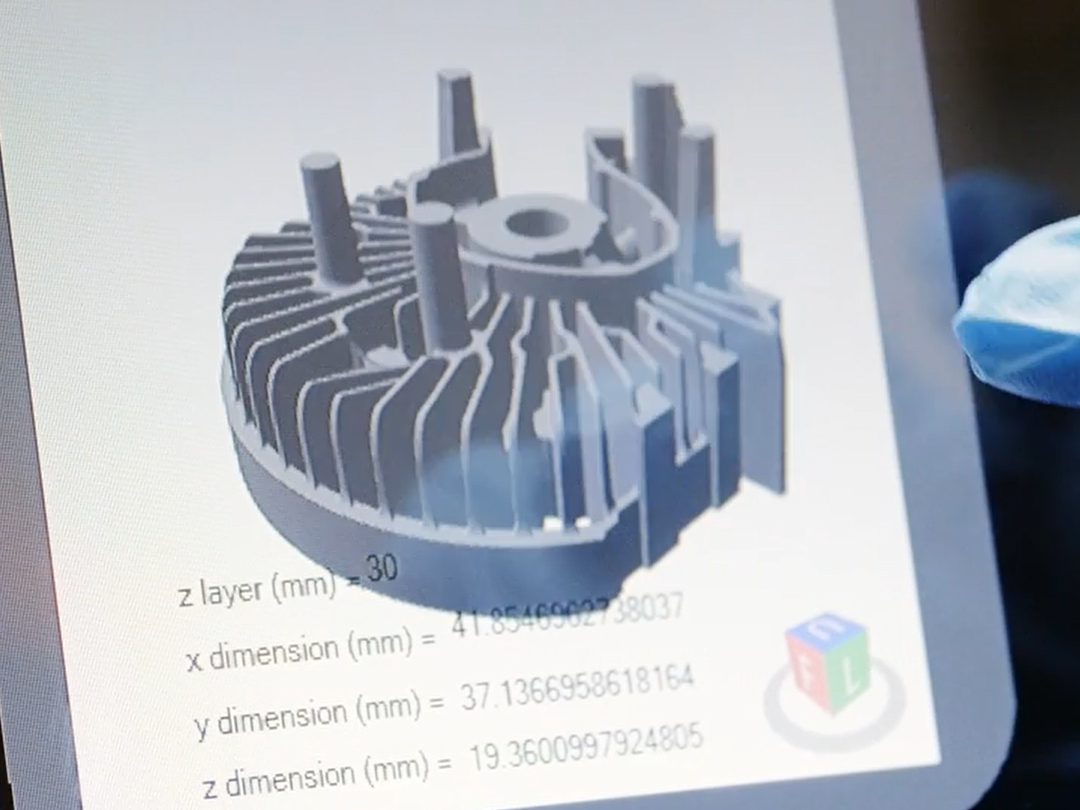

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy and export machine-readable files.

The system is equipped with a filter unit for recirculating gas within the working area. The filter unit maintains a high level of cleanliness and is easily adjustable thanks to the control installed on the interface. Gas flow within the chamber can be modified to optimise flow as required.

- Building volume: Ø 150mm; h=160mm

- Layer thickness: 0.02 – 0.12mm

- Laser: 1 x 300W IR fiber laser

- Laser spot diameter: 35 - 100μm (adjustable focus position)

- Heated platform: Up to 300°C

Materials

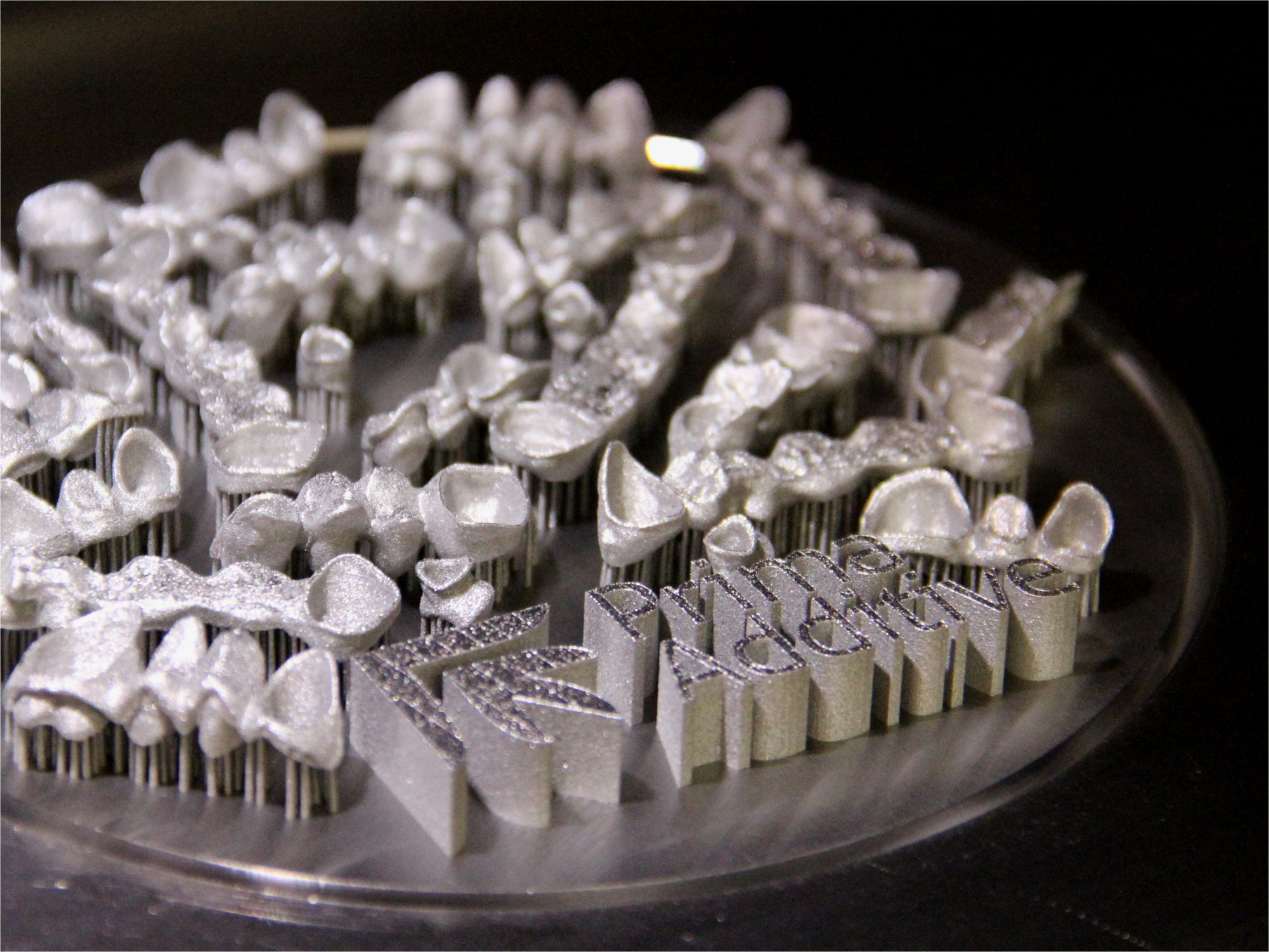

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminum alloy, high strength steel, copper alloy.

Prima Additive by Sodick helps you choose the right material for each application

Prima Additive by Sodick recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behavior of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive by Sodick can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Discover all the materials you can process with our PBF machines

Optimize your Prima Additive by Sodick machine

Software for PBF

Software for Powder Bed Fusion technology

All the support you need to prepare files for producing additive manufacturing parts.

Green Laser for PBF

Powder Bed Fusion technology

Green Laser for Powder Bed Fusion Technology.

Take advantage of our services

Application support

Transforming ideas into industrial reality

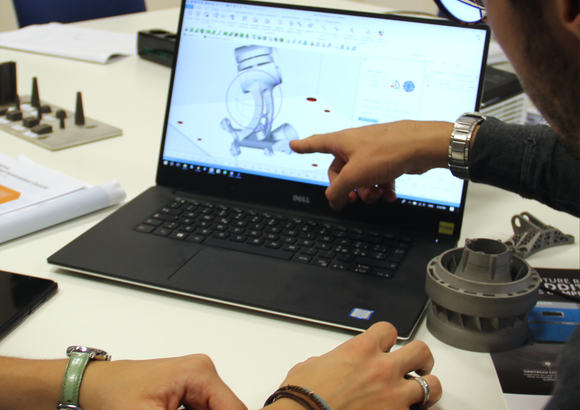

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive by Sodick. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

300 Family

Powder Bed Fusion Technology

High productivity and precision for medium and big-sized components manufacturing.

Print Genius 400

Powder Bed Fusion Technology