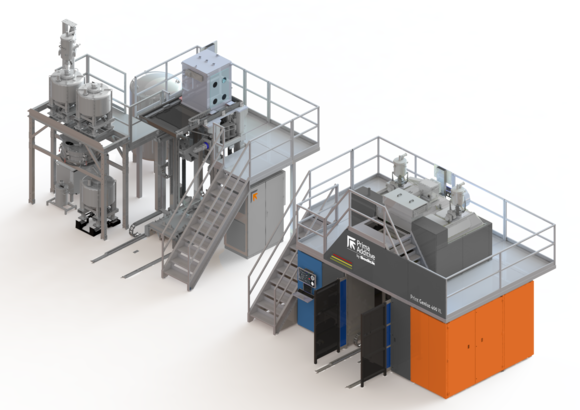

Print Genius 400

Powder Bed Fusion Technology

Highly automated solution for large components up to 1 meter high.

HIGH PERFORMANCE

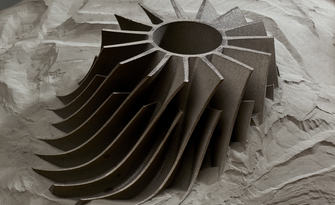

A platform designed to meet the specific needs of the aerospace sector and all sectors that require large components.

CONFIGURABLE

Both in terms of the height of the working volume and in terms of laser configuration: 2 or 4 lasers with the possibility of installing infrared or green lasers.

INNOVATIVE

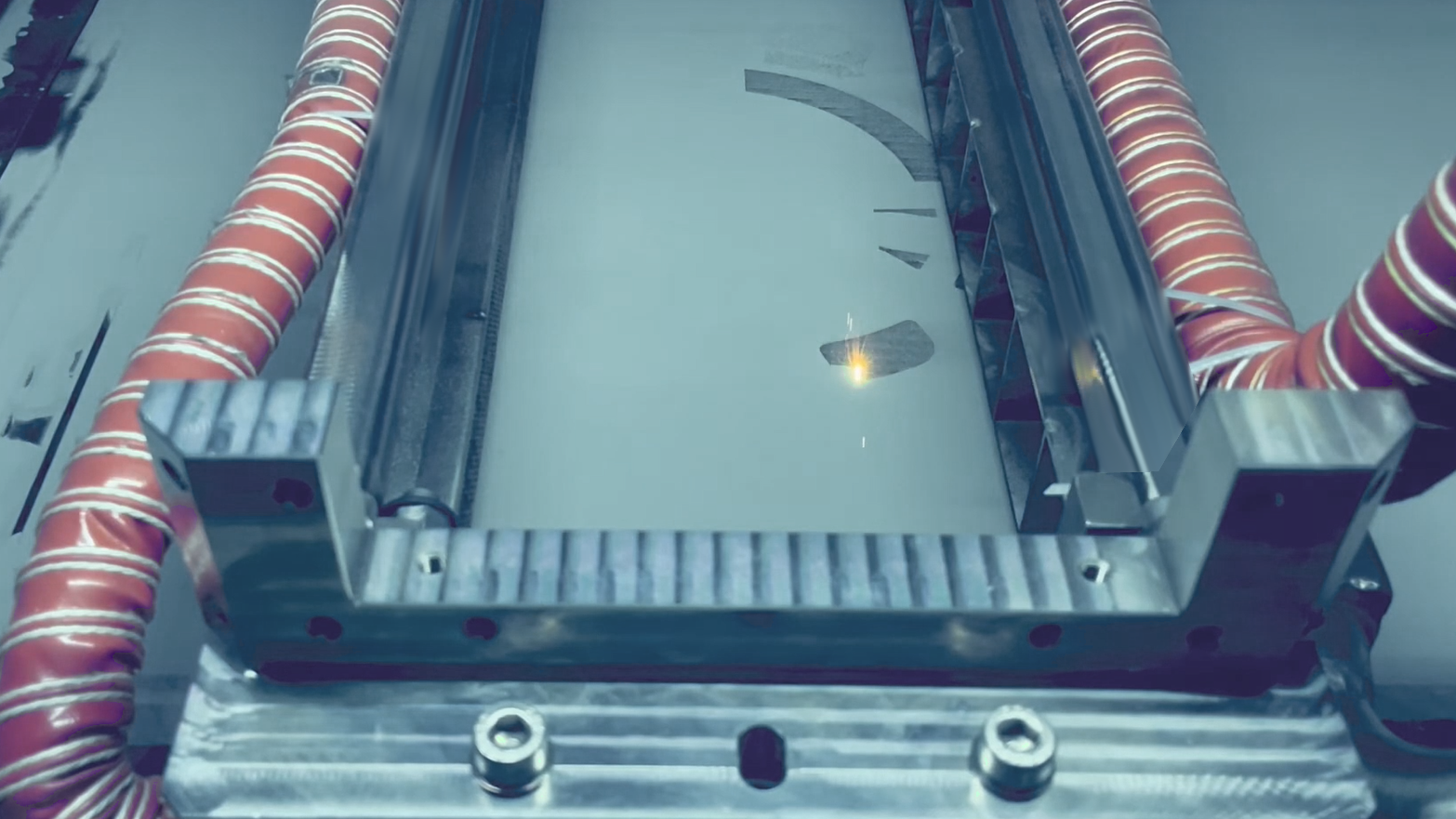

Localized suction additive process covered by 7 Prima Additive by Sodick patents.

AUTOMATED

Extractable working chamber, external depowdering unit and fully automated closed loop powder management.

A high-performance platform to produce large components: the solution that best suits the specific needs of the aerospace and automotive sectors.

Thanks to its patented localized aspiration system it allows to obtain exceptional results in terms of mechanical characteristics of critical components.

The extractable work chamber and the automatic powder loading system simplify the loading / unloading operations of the machine, increasing the overall productivity of the system.

Standard or XL

Platform 400 is available with two different working volumes. In its standard version it boasts an area of 430 x 430 x 600 mm, while in the Print Genius 400 XL version it is possible to build components up to one meter high, in line with the needs of the aerospace sector, for a working volume of 430 x 430 x 1000mm.

Different laser configurations possible

Like any Prima Additive by Sodick solution, the Print Genius 400 can also adapt to your needs with different laser configurations. In fact, it is possible to configure the machine with two infrared lasers, two green lasers, a "double wavelength" configuration with an infrared laser and a green laser, or four lasers which can be either infrared or green.

Innovative additive process with localized suction, covered by 7 Prima Additive patents.

Customizable laser configuration: Dual IR laser, Dual Green laser, Double Wavelength (IR + Green), Quad laser (IR or Green).

The system is equipped with an automatic work chamber extraction system, which allows the entire work chamber with the molded component inside and the remaining powder to be removed at the end of the job, to speed up the set-up activities. a new job, increasing the overall productivity of the system and allowing depowdering activities to be carried out in an external system.

Possible automation options available on request.

Variable focus position of the laser beam according to need, to always have the parameters optimized according to the application.

Double pre-heating system which allows to heat the surface of the powder bed both from above and from below.

Coaxial high speed pyrometer monitors temperature in real time and 2 cameras monitor process and powder bed.

Open parameters, suitable for carrying out research and development on processes and materials.

Easily adjustable filter unit thanks to the control installed on the interface.

- Building volume (Print Genius 400): 430 x 430 x 600 mm

- Building volume (Print Genius 400 XL): 430 x 430 x 1000 mm

- Build rate: 15-120 cm3/h (a seconda del materiale usato e dalla geometria del componente)

- Deposition layer thickness: 0.02 – 0.1mm

- Layer width: 0.1mm (single track width)

- Infrared laser power: 500 W IR single mode (Standard, optional more powerful lasers)

- Green laser power: 200 W Green single mode (Standard, optional more powerful lasers)

- Laser configurations: Dual laser IR, Dual laser Green, Double wavelength (IR + Green), Quad laser IR, Quad laser Green

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy.

Prima Additive by Sodick helps you choose the right material for each application

Prima Additive by Sodick recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive by Sodick can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Discover all the materials you can process with our PBF machines

Optimize your Prima Additive by Sodick machine

Automated Powder Management System

AUTOMATION FOR POWDER BED FUSION

Depowdering, sieving and powder recycling in closed loop.

Software for PBF

Software for Powder Bed Fusion technology

All the support you need to prepare files for producing additive manufacturing parts.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive by Sodick. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

300 Family

Powder Bed Fusion Technology