Suitable materials for Direct Energy Deposition

Direct Energy Deposition technology

Direct Energy Deposition technology

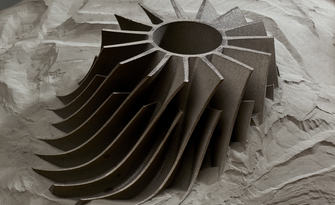

Make large parts, cladding or repair high-value metal components with additive manufacturing becomes particularly cost-effective, fast and simple. But what materials to use for Direct Energy Deposition processes?

To select the most suitable ones, you can always count on our qualified support, who will provide you with all the technical information you need and with whom you can plan assessment tests before going into production.

Prima Additive by Sodick will also guide you when you choose Directed Energy Deposition technology.

Find out now which materials are perfect for your Laser Metal Deposition production needs.

Prima Additive by Sodick offers you a complete selection of metal powders ranging from steel to nickel, from cobalt chrome to copper and even titanium alloys; the latter can be processed thanks to the inert chamber option or the inert head configuration with gas shielding available on our machines.

Ready to achieve optimum standards in your production? Start matching the right metal to your Prima Additive by Sodick machine now.

Materials for Direct Energy Deposition

Materials for Direct Energy Deposition

Materials for Direct Energy Deposition

Materials for Direct Energy Deposition

Materials for Direct Energy Deposition

Application support

Open innovation

Circular economy inspired

© Prima Additive S.r.l. | Corso Re Umberto, 54 - 10128 Torino (TO) Italia | Share Capital € 116.860,77 fully paid up | VAT 11434740012 - C.C.I.A.A.Torino 1213183 | Reg. Impr. Torino n. 11434740012