Prima Additive presents its solutions with Powder Bed Fusion (PBF) technology at BIMU 2020 (Hall 9 Stand C37A): the new family of Print 150 series machines, in world premiere, and the well-known and consolidated Print Sharp 250.

Prima Additive exhibits with 3D New Technologies S.r.l. (3D-NT), the start-up with which Prima collaborates for the creation of innovative machines for Additive Manufacturing completely designed and built in Italy. The collaboration with 3D-NT is the result of the Open Innovation strategy of the Prima Industrie group and combines the experience and solidity of an Innovation Leader with young and dynamic entrepreneurship, characterized by high flexibility and speed of response to new technological trends.

At the first Italian fair that opens its doors after months of forced pause due to the health emergency, the Prima Industrie group focuses on smart and sustainable innovation for 3D printing of metals.

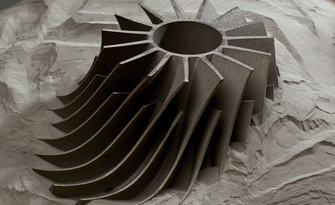

Presented in absolute preview, the new 150 series by Prima Additive is composed of three models: Print Sharp 150, Print Genius 150 and Print Green 150, specialized for different applications and levels of productivity, thanks also to the use of the 250 or 200 laser W with specific configurations: Single laser, Dual laser and Green laser.

Prima Additive 150 series is Industry 4.0 ready and allows the integration of monitoring sensors and connection through different standards for IoT functions.

The machines of the 150 series are characterized by a construction volume with a diameter of 150 mm and a height of 160 mm and allow you to vary the size of the laser beam spot as needed, to always have the parameters optimized according to the application. The double pre-heating system allows to heat the surface of the powder bed both from the top and from the bottom through the heated plate. The high speed coaxial pyrometer monitors the temperature in real time. The 150 series has 2 cameras for monitoring the process and the powder bed. The system is open parameters suitable for research and development on the process and on materials. In particular, the Print Green model is exhibited at BIMU, with a green laser for processing pure copper.

Another solution on display in the Prima Additive stand is the Print Sharp 250, its medium volume machine for Powder Bed Fusion applications. Due to its characteristics, the Print Sharp 250 represents the ideal entry level solution for those who want to explore the potential of additives thanks to a consolidated product with an excellent quality-price ratio.

Designed to make operations easier and more efficient, the Print Sharp 250 features intelligent control software and a simple, intuitive interface. In addition, the machine is equipped with an integrated glovebox and a plug-in for the aspirator: in this way the operator can work on the system without coming into contact with metal powder. The ease of use also allows you to increase its use rate and performance.

With a build volume of 250x250x300mm, the Print Sharp 250 ensures high component quality in terms of surface and mechanical characteristics. It is also possible to combine post-processing solutions with the machine in case of more specific applications requiring higher parameters.

"Add Something New", the slogan chosen by Prima Additive for the BIMU fair, is an invitation to exploit the potential of additive manufacturing solutions. The systems presented by Prima Additive allow you to experiment with new, sustainable and competitive technologies with the security of a support that covers the entire life cycle of the product to maximize the investment and added value for the customer.