Prima Additive brings its most advanced Made in Italy technologies to Formnext 2022

Prima Additive will present its highly innovative and smart solutions at the Formnext fair in Frankfurt am Main from 15 to 18 November (Hall 12.0, Stand E81).

Do you want to come and visit us at Formnext? Request a free ticket:

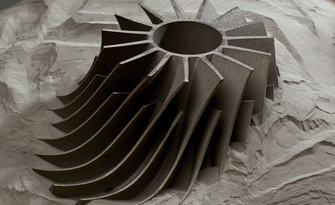

For the Powder Bed Fusion technology Prima Additive is showing the Print Green 150, a solution based on the 150 platform, with a cylindrical working area of 150 x 160 mm. The machine is equipped with a 200 W green laser, ideal to reach excellent levels of quality and repeatability in the processing of highly reflective materials such as pure copper. The green laser on reflective materials, in fact, solves the main problems of absorption, process stability, and poor efficiency that normally arise when these alloys are processed with infrared lasers. Prima Additive's developments in the use of green lasers have led to excellent results on pure copper, with densities above 99.9%.

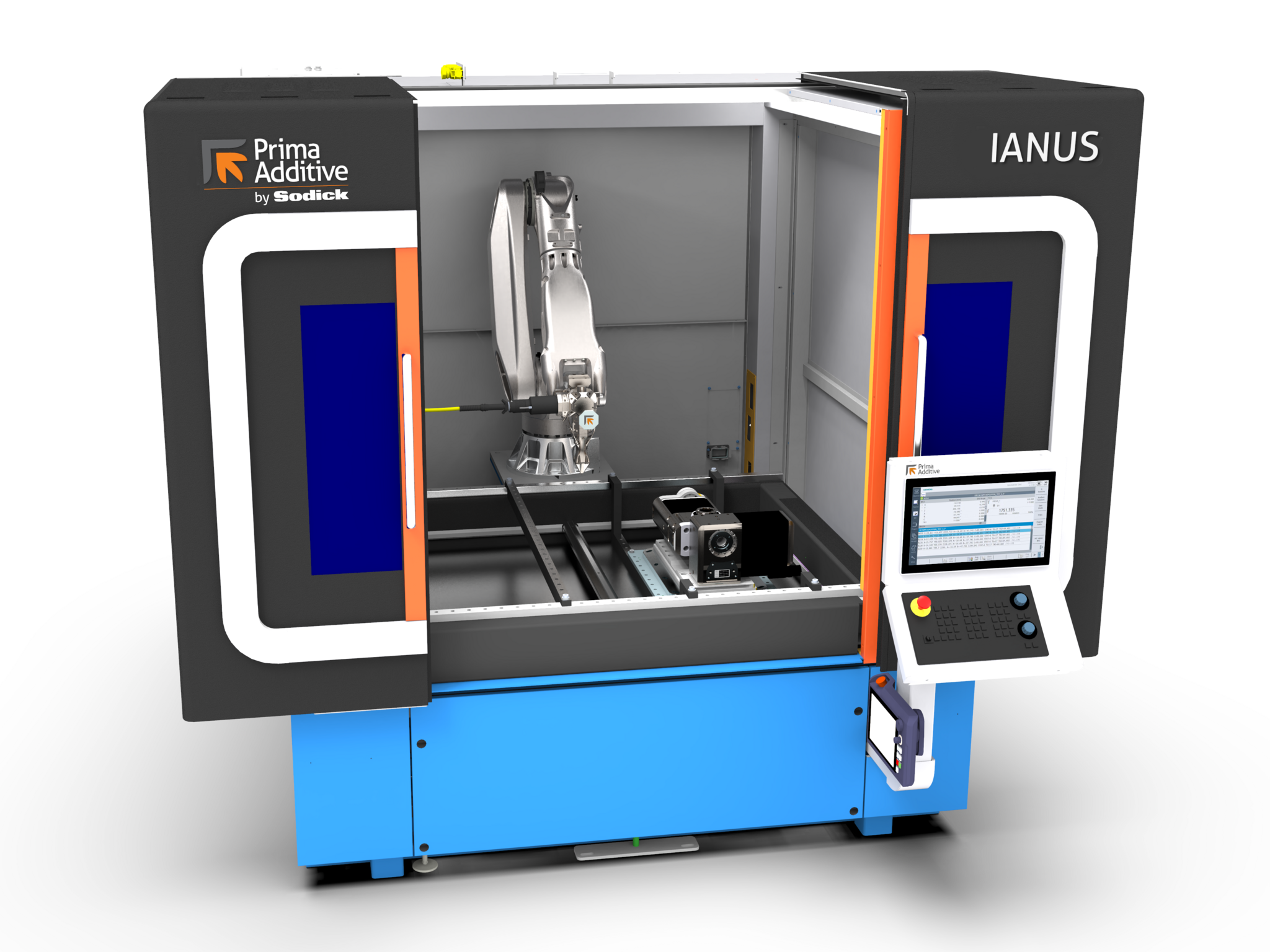

For Direct Energy Deposition technology, the new IANUS laser processing robotic cell is showcased at Formnext. Equipped with a working area of 1600 x 1200 x 700 mm, this solution stands out for its ability to be configured for different processes. In fact, in addition to the head for direct deposition based on powder, it is possible to configure the machine for direct energy deposition based on metal wire or for other laser processes such as remote welding or laser hardening. The machine is designed in such a way as to offer the possibility of multiple configurations with more than one laser process, thanks to a quickly changeable head. The name chosen for the new product derives from Roman mythology: Ianus is the god of the beginnings and duality with two faces, just as the new robotic cell marks an important innovation in additive technology and can be equipped for two different laser processes.

This system presents a series of functional solutions for its inclusion in the factory of the future. In fact, it was developed by Prima Additive in collaboration with Siemens, a leading company in automation and digitalization with specific skills in the field of robotics and additive manufacturing. The integration between the technologies of Siemens and those of Prima Additive is expressed, first of all, through the integration of the robotic arm and the CNC, through the Sinumerik Run MyRobot / Direct Control functionality. Through this functionality, the user of the machine will be able to interface with the robotic cell using a single control console but above all, he will be able to carry out the movement and programming of the robot using typical instructions of a machine tool, thus exempting him from knowing an additional programming language specific for robots. The integrated use of the CAD-CAM-CNC chain, made possible using the NX platform and the Sinumerik One numerical control, is completed by the integration of digital solutions and data management.

The solution, based on the MindSphere open ecosystem, involves the use of Siemens Apps that allow you to view, manage and optimize production, such as Manage MyMachine, and remote monitoring and control systems, such as Manage MyMachine / Remote. To complete this digital offer, we find some specific applications, able to manage high-frequency data, based on the Industrial Edge for Machine Tools platform from Siemens.

To fully exploit the potential of Sinumerik One, the winning choice was to use the Create MyVirtual Machine, a key tool made available by the Siemens digital portfolio. This software is in fact able to generate a real digital twin of the system and has proved to be extremely useful for facilitating the engineering work in the various stages of development and optimization of the machine, also allowing a considerable reduction in time to market.

All Prima Additive solutions on display at Formnext are Made in Italy and leverage the deep-rooted experience of Prima Industrie Group in laser processing and automation. This translates into high technological and quality levels and an important benefit in a time in which supply chains are an increasingly critical factor for manufacturers.

Prima Additive's strength lies not only in the machines, but also in the ability to guide customers throughout the additive manufacturing adoption process. Prima Additive experts will be available at the stand to provide advice to all those who want to know more about this technology, helping them understand how to best combine metal additive manufacturing with traditional mechanical technologies, identify the most efficient ways to produce their components and discover every secret of this technology to make the most of it.

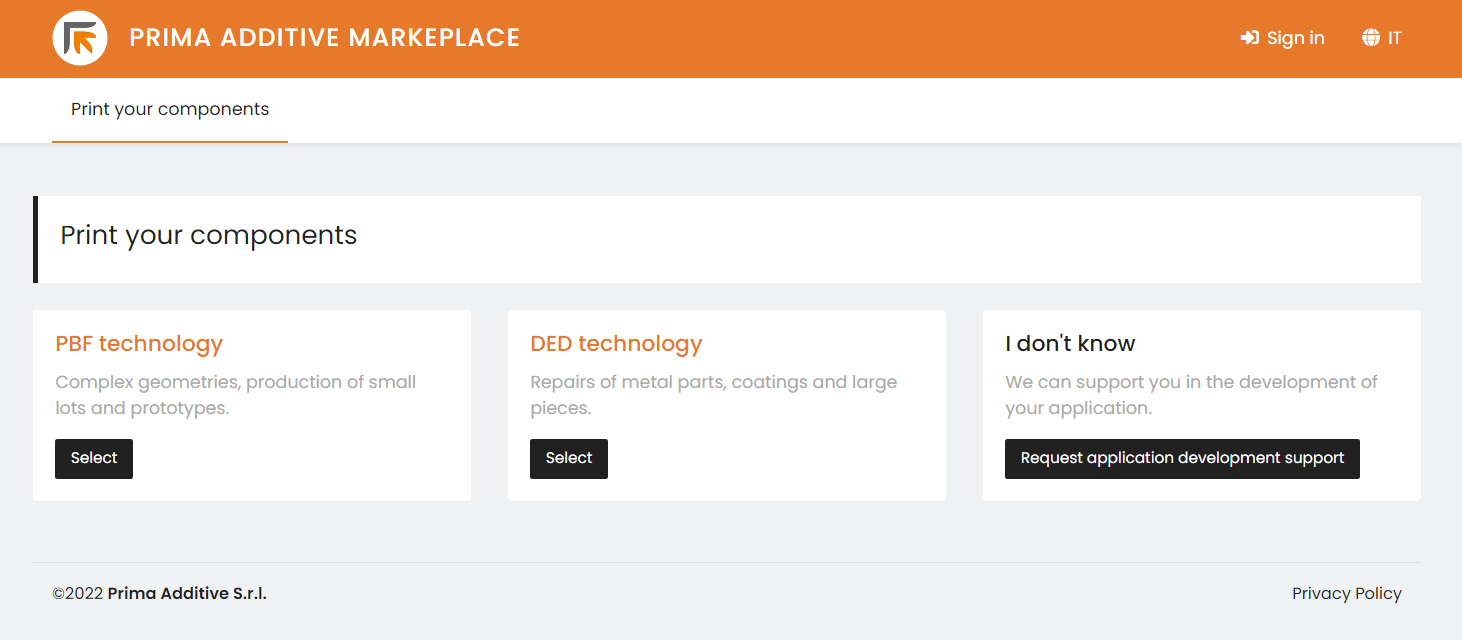

In line with this principle, another big news for Prima Additive is the new platform "Prima Additive Marketplace", which represents one of the efforts of the Turin-based company in the direction of reducing the barriers to entry of metal additive manufacturing, while making production increasingly digitized. Through this platform, accessible at https://marketplace.primaadditive.com and created in collaboration with Morphica, the innovative Italian SME that provides 3D printing services, it will be possible to request the creation of metal components, starting from a file 3D.

The Prima Additive Marketplace leverages the production capacity of Prima Open Additive Labs, the network of companies, universities, and research centers that provide support on additive manufacturing, and Prima Additive customers to provide an on-demand production service, which can make the metal additive manufacturing accessible even to companies that do not have the possibility or the volumes necessary to have their own system.

In addition to the possibility of directly requesting the printing of the component, on the platform it is also possible to obtain dedicated consultancy, functional to the realization of an application study, with which to explore the potential of additive manufacturing on the specific case of the customer, analyzing the opportunities for the engineering of its component and identifying the main advantages and possible criticalities.

Do you want to come and visit us at Formnext? Request a free ticket:

Prima Additive's participation in the Formnext tradeshow is co-financed through the call for proposals "POR FESR 2014/2020 - SC-UP - application code 353 – 49"