Maximizing ROI in Metal Additive Manufacturing: A Prima Additive Perspective

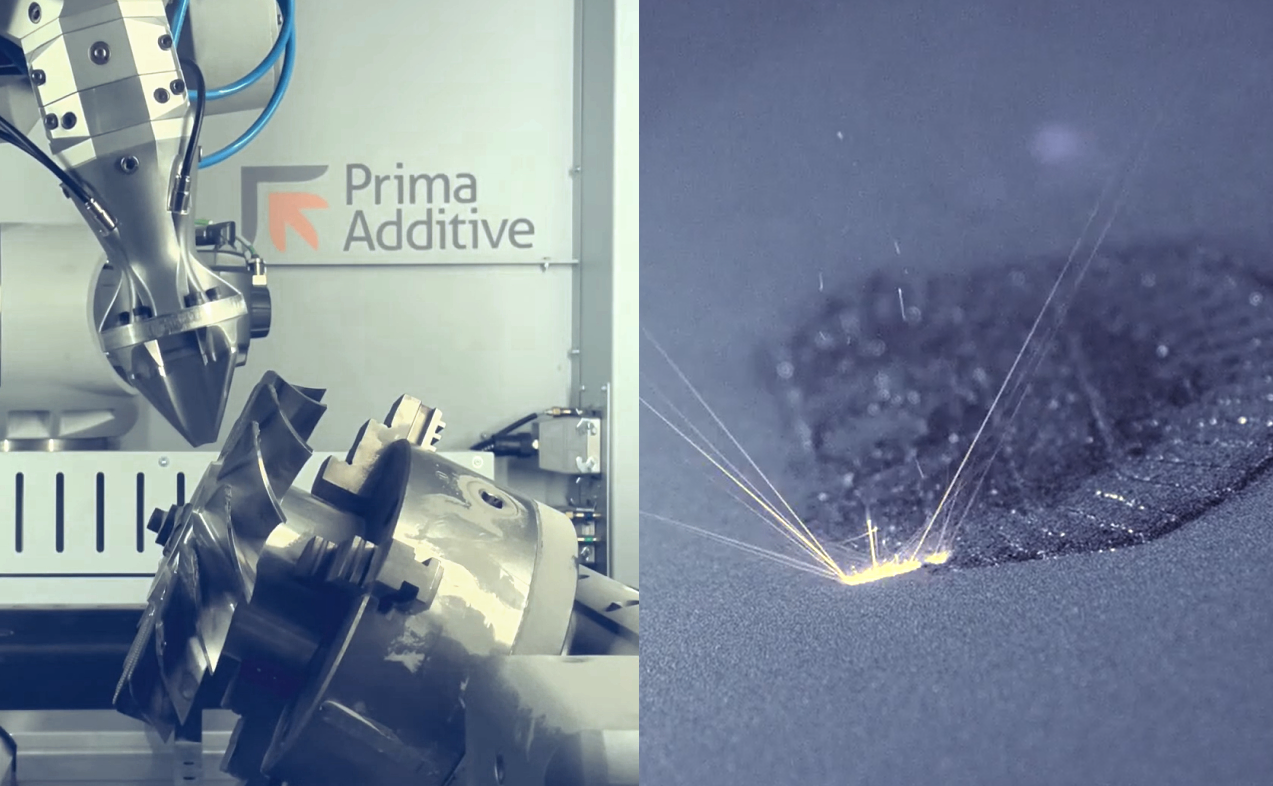

In the dynamically competitive global market, making wise investments in production systems is more than just a choice; it's a necessity for businesses across all sectors. Prima Additive, a leader in this technological revolution, collaborates with a wide array of industries. These include aerospace, automotive, energy, and the medical field, along with tooling and mechanical sectors. Each of these industries faces its own set of challenges and demands, and our expertise in Additive Manufacturing provides bespoke solutions that address these unique needs.

In the realm of modern manufacturing, the adoption of cutting-edge technologies serves as the keystone for businesses aiming not only to thrive but to revolutionize their industry. Prima Additive, standing at the forefront of metal additive manufacturing, champions this paradigm with a creator's zeal. As pioneers in a domain defined by change, competitiveness, and innovation, we offer insights into the realm of Return On Investment (ROI) for metal additive manufacturing — a critical consideration for businesses navigating the waters of new technological adoption.

At Prima Additive, we don't just pride ourselves on supplying top-tier Additive Manufacturing machines. We are committed to being a trusted partner, offering insightful consultations on the profitability and cost-effectiveness of Additive Manufacturing in various industrial contexts.

Understanding ROI in New Manufacturing Technologies

The concept of ROI in the adoption of new production technologies transcends mere financial returns. It encapsulates the value generated through innovation, efficiency, and competitive edge. Metal additive manufacturing, with its promise of transforming production processes, necessitates a comprehensive ROI analysis that goes beyond initial cost outlay to include factors such as product lifecycle, market responsiveness, and bespoke production capabilities.

Key Variables in Metal Additive Manufacturing ROI

For businesses considering Additive Manufacturing, it's crucial to adopt a holistic view that encompasses not only the direct costs associated with production but also the broader strategic benefits. Additive Manufacturing offers advantages in flexibility, customization, and the ability to produce complex designs that traditional manufacturing processes cannot easily replicate. These advantages can lead to new market opportunities and revenue streams, especially for industries where customization and rapid product development are key competitive factors.

Furthermore, understanding the cost drivers and economic scales unique to Additive Manufacturing is essential. Unlike traditional manufacturing, Additive Manufacturing may not always benefit from increased scale in the same way. This understanding can inform strategic decisions about production volumes, design optimizations, and investment in technology and training.

- Cost Efficiency: The direct costs associated with metal additive manufacturing—material, operation, and maintenance—are often the primary focus. However, evaluating ROI requires a broader lens. The technology's ability to reduce waste, coupled with its energy efficiency, often offsets the initial higher costs, delineating a path to long-term savings.

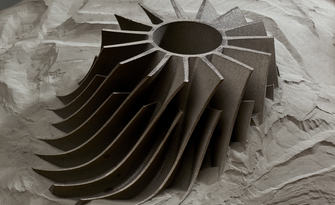

- Design Freedom and Innovation: One of the most compelling advantages of additive manufacturing is the unparalleled design freedom it offers. This capability allows for the creation of parts that are both lighter and more complex than those produced through traditional methods. For industries where customization and innovation drive value, this aspect significantly contributes to a higher ROI.

- Time to Market: Additive manufacturing accelerates the development cycle, from prototype to final product. This rapid pace not only reduces time to market but also enables a more agile response to customer needs and market trends, enhancing competitiveness and potential revenue streams.

- Supply Chain Simplification: The ability to produce parts on demand and on-site addresses several supply chain vulnerabilities, including inventory costs, logistics, and production bottlenecks. This simplification and flexibility support a leaner, more responsive operation, positively impacting ROI.

Actionable Insights for Maximizing Metal Additive Manufacturing ROI

To fully leverage the ROI of metal additive manufacturing, businesses should consider the following strategies:

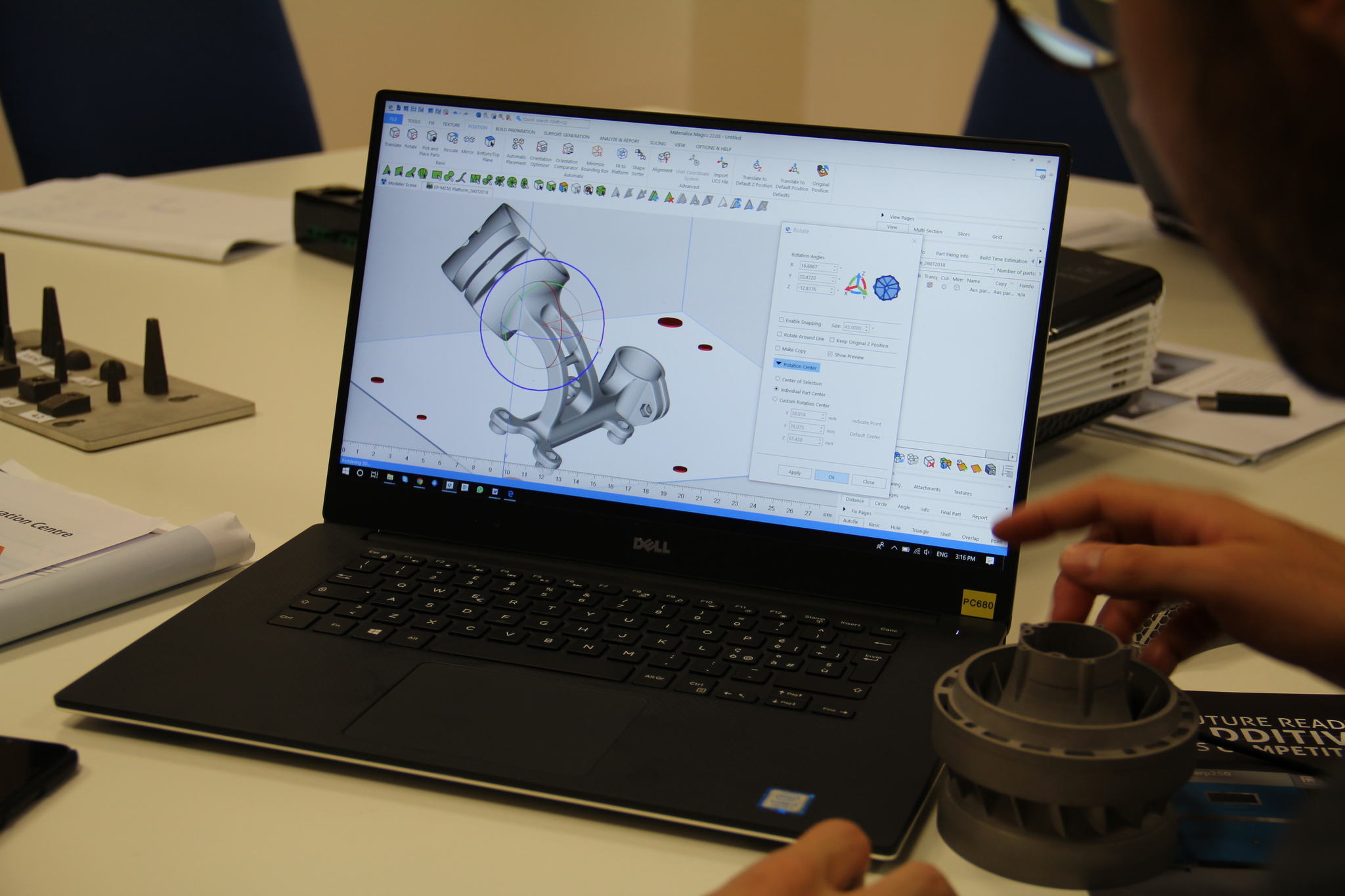

- Comprehensive Cost-Benefit Analysis: Before adoption, conduct a thorough cost-benefit analysis that extends beyond immediate financial implications to include long-term savings, efficiency gains, and competitive advantages.

- Leverage Design for Additive Manufacturing (DfAM): Invest in training and development around DfAM to fully exploit the technology's potential for innovation and efficiency.

- Integrate into the Supply Chain: Assess and adapt your supply chain to incorporate additive manufacturing where it offers the most significant benefits in terms of responsiveness and cost-efficiency.

- Focus on Niche Markets: Identify and target niche markets where customized and complex parts can command a premium, thus maximizing the value derived from additive manufacturing capabilities.

- Continuous Innovation and Learning: Adopt a culture of continuous innovation and learning to stay ahead of technological advancements in additive manufacturing, ensuring your business remains competitive and adaptable.

Our engagement with clients extends beyond the initial investment decision. We are dedicated to maintaining an ongoing dialogue, providing expert advice and insights both during the decision-making process and in the post-sale phase. This commitment ensures that our clients can fully leverage the advantages of Additive Manufacturing to enhance their business operations.

Additive Manufacturing, as we've discussed, offers substantial economic benefits. It's a technology that not only boosts efficiency and reduces costs but also respects the environment. This approach to manufacturing aligns with the growing global emphasis on sustainability. With Additive Manufacturing, companies gain the ability to reduce material waste, lower their carbon footprint, and embrace a more eco-friendly production method.

At Prima Additive, we see ourselves not just as suppliers but as partners in our clients' journey towards embracing the transformative potential of metal additive manufacturing. By understanding and maximizing the ROI of these technologies, businesses can unlock new horizons of efficiency, innovation, and competitiveness. Embracing change, fostering innovation, and striving for competitiveness are not just values; they are the roadmap to a future where every creator can leave an indelible mark on the world of manufacturing.

We invite you to contact Prima Additive for an initial meeting to explore how we can collaborate. Together, we can assess your specific needs and determine how Additive Manufacturing can drive your business forward, both economically and sustainably. Reach out to us, and let's start a conversation about shaping the future of your manufacturing.