Prima Additive and SAFINA start a partnership for the development of new materials

Prima Additive is pleased to announce the achievement of a partnership agreement with SAFINA a.s.

SAFINA is a company established in 1920, has a long tradition in the jewelry and precious metals sector and today has a wide range of products, including metal powders for additive manufacturing. SAFINA has directed its production of powders mainly to copper, copper alloys, and precious metal powders. SAFINA laboratories are equipped with a wide range of measuring devices. Thanks to this, they are able to guarantee the quality of the powders throughout the entire production process.

SAFINA is a company with nearly 200 employees with branches in the Czech Republic, Slovakia, Poland, Romania, and the USA and sells its products all over the world.

By combining Prima Additive's experience as a machine builder with SAFINA's as a materials expert, it will be possible to allow both companies to achieve important steps forward in process optimization, to make additive increasingly competitive and unlock new application fields, as well as new markets.

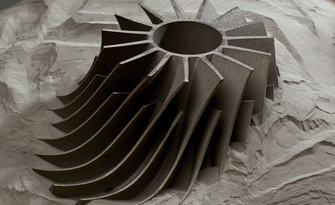

SAFINA will equip itself at its application centre with a Prima Additive machine based on powder bed fusion technology, the Print Genius 150 Double Wavelength, featuring a build volume with a diameter of 150 mm and a height of 160 mm. What makes this machine unique is the innovative configuration of the laser sources: a 500 W infrared laser and a 200 W green laser, which can work alternately in the same work area. In this way, it is possible to select the best wavelength for optimizing the material absorption of the laser radiation. For instance, it's possible to choose IR radiation for steel alloys, titanium, nickel, cobalt-chrome, or green radiation for pure copper, aluminum, or other highly reflective materials.

SAFINA and Prima Additive will work together to improve the process on some copper-based alloys, including CuCrZr, CuCrNb, and CuAg30.

«We are very proud to announce this agreement – says Paolo Calefati, CEO of Prima Additive – because we have recently noticed an increase in requests for applications in special materials. This partnership allows us to continue our developments on the process, with particular reference to some of the most promising sectors for the use of additive manufacturing, such as aerospace and jewellery. Our solutions, thanks to their green laser source, are the optimal response to the need to process highly reflective materials and we are sure that SAFINA is the ideal partner to further increase the quality, reliability, and repeatability of the process»

SAFINA's application center, located in Prague (Czech Republic), following the installation of the Print Genius 150 Double Wavelength will also act as Prima Additive's application center for Eastern Europe, providing a local touchpoint for Prima Additive, but above all a fundamental support to those who want to explore additive manufacturing or to those who need application studies.

Petr Štefek, Head of Additive Manufacturing, SAFINA adds: «We are hopeful that this partnership will accelerate the development of new materials of copper alloys and precious metals for additive manufacturing and enable the company to significantly expand its portfolio of services. The installed Prima Additive machine will, we hope, be the first of many planned installations in future years so that the company will be able to offer development and production capabilities to its partners. We look forward to the challenges associated with a newly formed partnership with such an ambitious company as Prima Additive».