"Good to Grow", the slogan with which Prima Additive, the business unit of the Prima Industrie group dedicated to metal additive solutions, presents itself at EMO from 4 to 9 October (Hall 5, Stand B10 / C11), could not be more suitable for the Milan exhibition appointment.

The context in which the fair takes place seems to be extremely promising, thanks to the forecasts of growth in demand for machine tools in the main areas of the world, the important Transition 4.0 incentives introduced by the Italian government, and the renewed enthusiasm for the return of trade fairs in presence - in total safety also thanks to the strict health protocols drawn up by the national government, the fair organizer, and the exhibitors themselves.

In addition to this encouraging scenario, at the Prima Additive stand visitors will find great confidence in the potential of additive solutions for the growth and renewal of manufacturing companies and the opportunity to discover two "future-proof" metal 3D printing products: innovative, sustainable, interconnected and totally compatible with Industry 4.0.

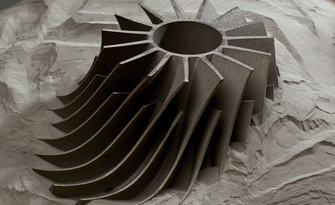

PrIma Additive presents the new Print Genius 150 as a preview at EMO. The machine, which is part of the Prima Additive product line with Powder Bed Fusion (PBF) technology, is equipped with two 300 W infrared lasers that can work simultaneously on the same work area. With this machine it is possible to process steel, aluminum, titanium, nickel, chromium-cobalt and copper alloys with high productivity and quality.

Print Genius 150 is equipped with a build volume with a diameter of 150 mm and a height of 160 mm and features all the innovations of Prima Additive's PBF solutions, including a system to vary the position of the laser beam focus which optimizes the parameters according to the application, a double preheating system to heat the surface of the powder bed both from the top and from the bottom through the heated plate (up to 300 ° C), a high speed coaxial pyrometer for the control of the real-time temperature and 2 cameras for monitoring the process and the powder bed.

Prima Additive 150 series is Industry 4.0 Ready and allows the integration of monitoring sensors and the connection through different standards for IoT functions. Again with a view to smart manufacturing, as a partner of MindSphere World, Prima Additive participates in the interconnection project of the fair, to allow all visitors to better understand the infinite potential of the MindSphere platform in the field of IoT systems for industrial use.

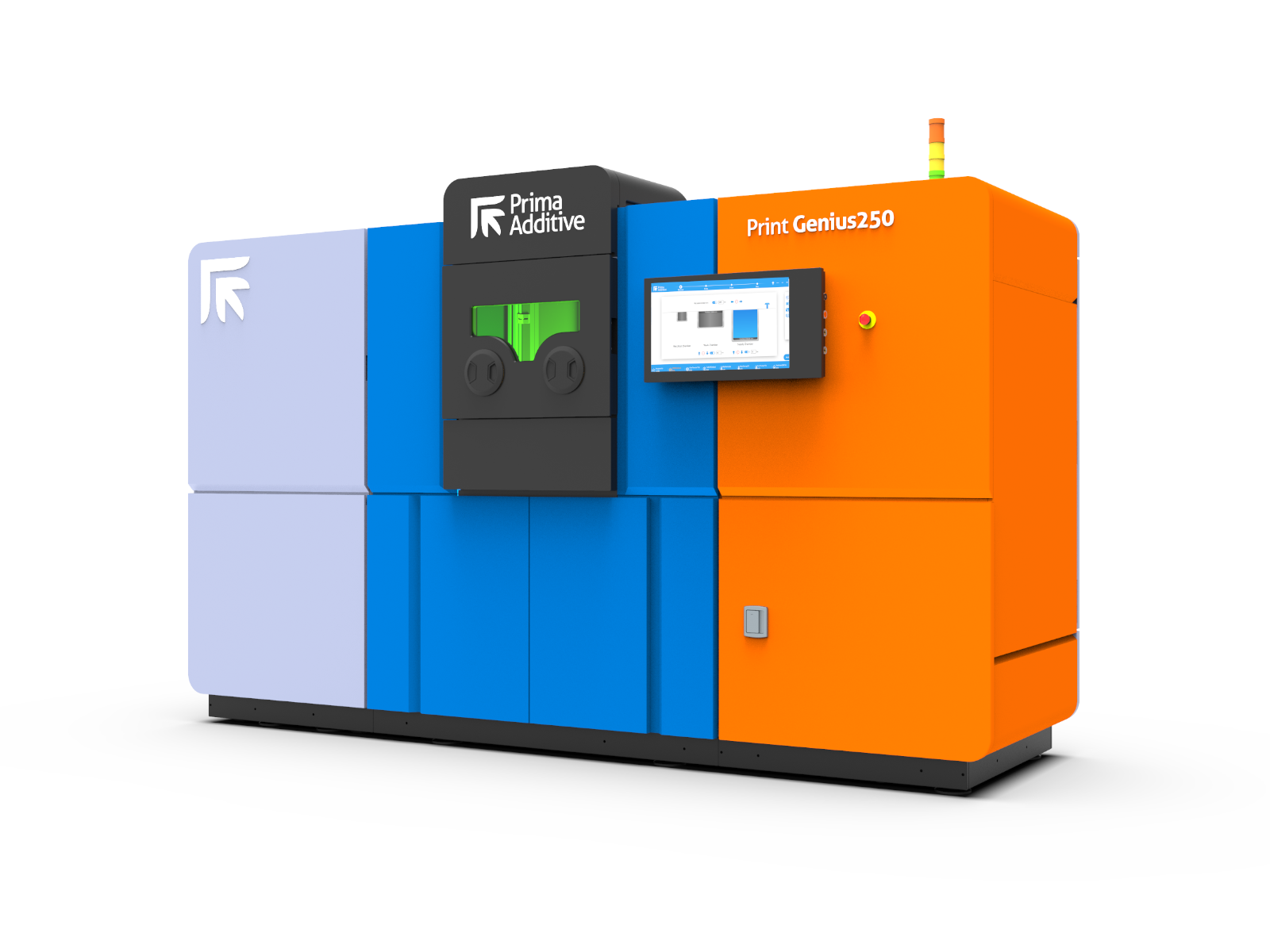

Another solution on display in the Prima Additive stand is the Print Genius 250, the ideal solution for high productivity metal printing applications, being able to reduce production times thanks to its 500 W single-mode dual laser, combined with an intelligent software for a quick orientation of the pieces and for the definition of the machine parameters.

The build volume of 258x258x350 mm makes the machine suitable for the production of medium sized components. The optimized gas flow, resulting in reduced consumption to a minimum, and the ability to change the material completely in less than 2 hours are other strengths of this innovative machine. Print Genius 250 is equipped with a dual-line filter unit for the recirculation of the gas inside the work area, which maintains a high degree of cleanliness of the machine and minimizes the replacement of parts subject to wear. The new HMI allows you to monitor the construction environment in real time and generate reports with all the main printing parameters.

The Print Genius 250 is suitable for a wide range of materials: stainless steel, maraging steel, high temperature nickel based alloys (Inconel), titanium, cobalt-chromium, aluminum, copper and high hardness steels for the mold sector.

Prima Additive exhibits with 3D New Technologies S.r.l. (3D-NT), the start-up with which the Prima Industrie group collaborates for the creation of innovative machines for Additive Manufacturing completely designed and built in Italy. The collaboration with 3D-NT is the result of the Open Innovation strategy of the Prima Industrie group and combines the experience and solidity of an Innovation Leader with young and dynamic entrepreneurship, characterized by high flexibility and speed of response to new technological trends.

EMO 2021 will not be the only opportunity in the coming months to discover how the Prima Group's metal additive manufacturing solutions can help companies grow their business: from 26 to 28 October Prima Additive will be present at the AddIT 3D fair in Bilbao, from 26 to 29 October will exhibit at Blechexpo in Stuttgart, for the first time together with Prima Power, the brand specialized in laser and sheet metal processing machinery of the Prima Industrie group, and from 16 to 19 November at Formnext in Frankfurt will be presented the complete range of Prima Additive technologies which includes both Powder Bed Fusion and Direct Energy Deposition systems.