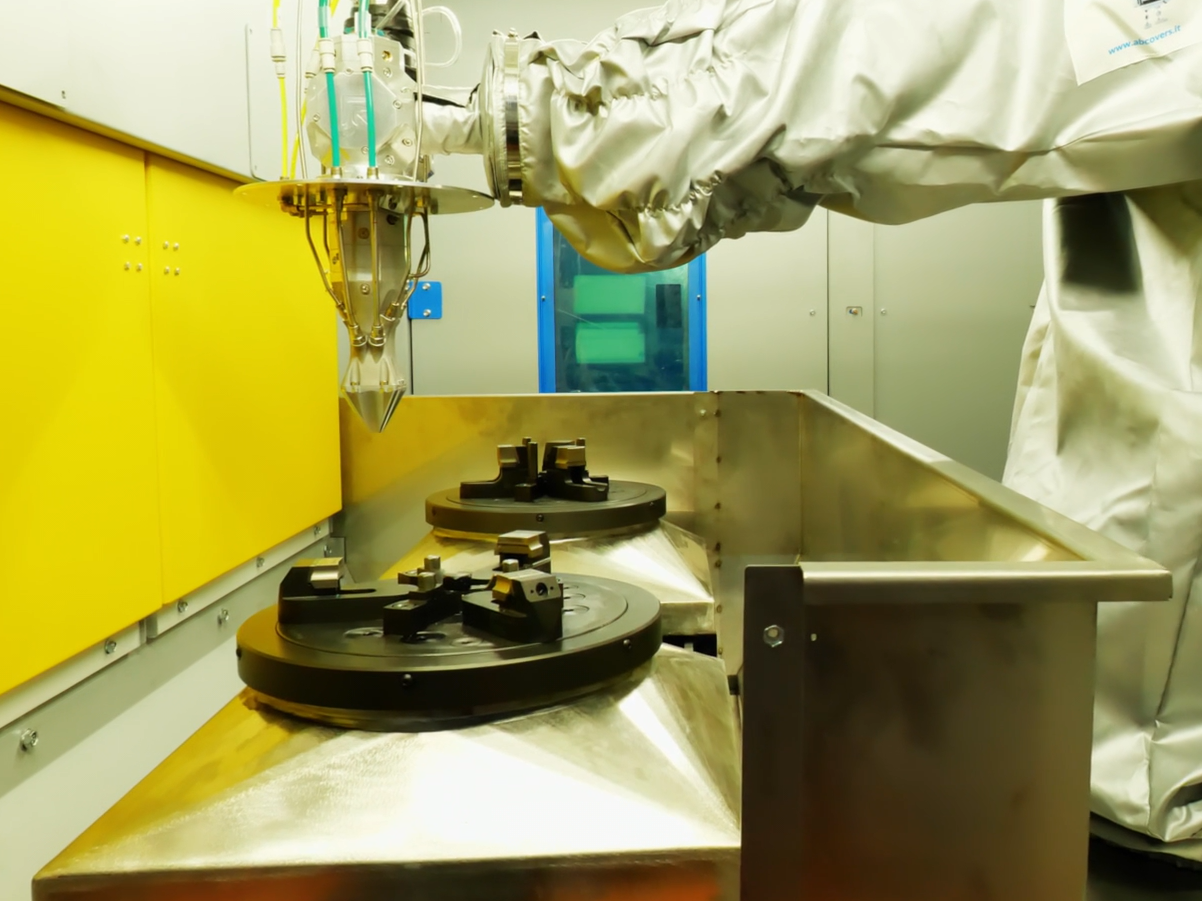

Rapid Coating Cell

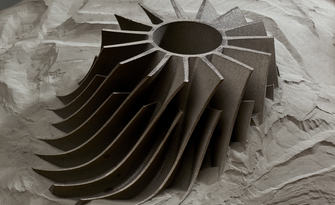

Direct Energy Deposition technology

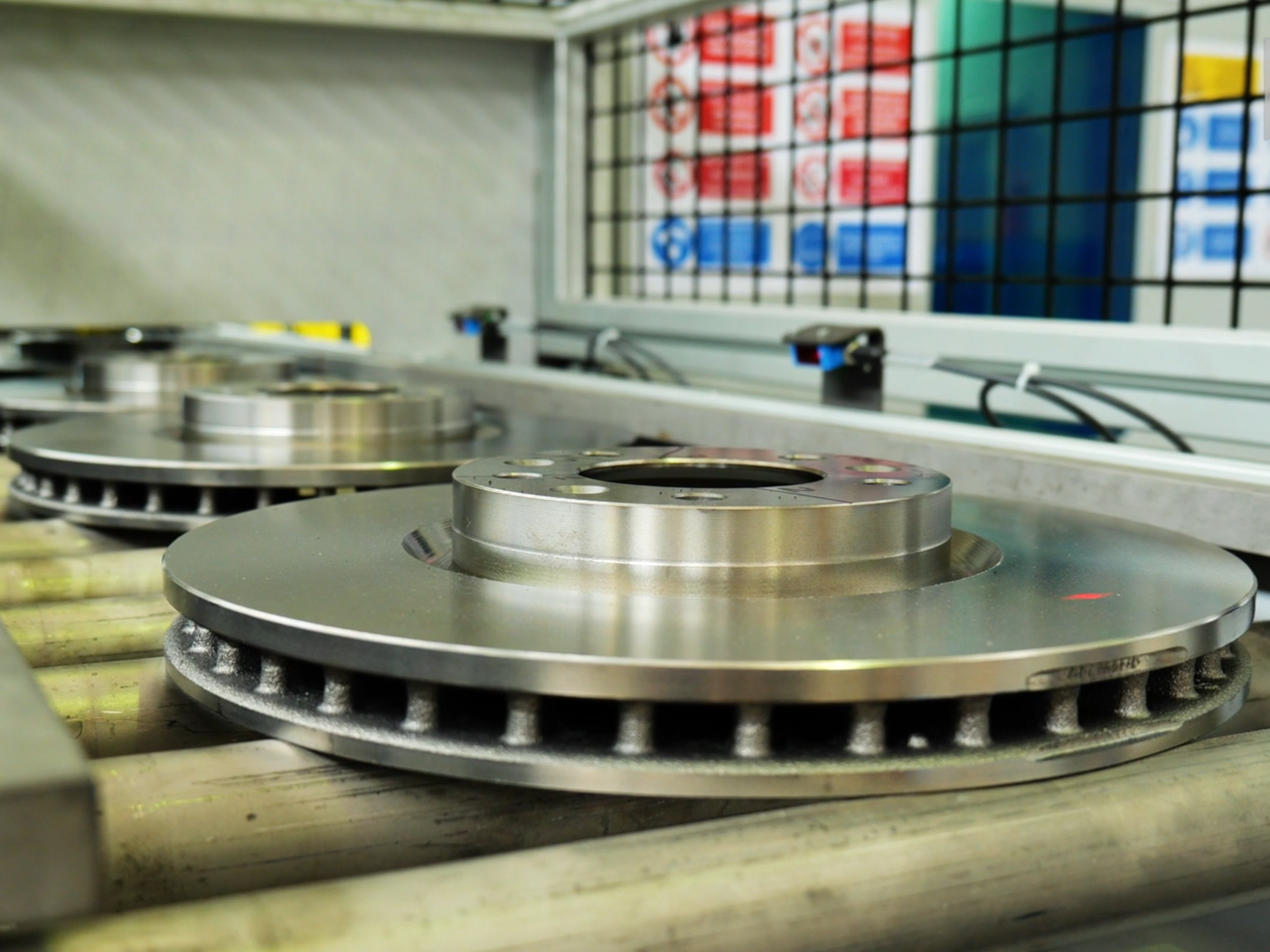

Efficient, sustainable high-speed laser cladding for brake discs at any production level.

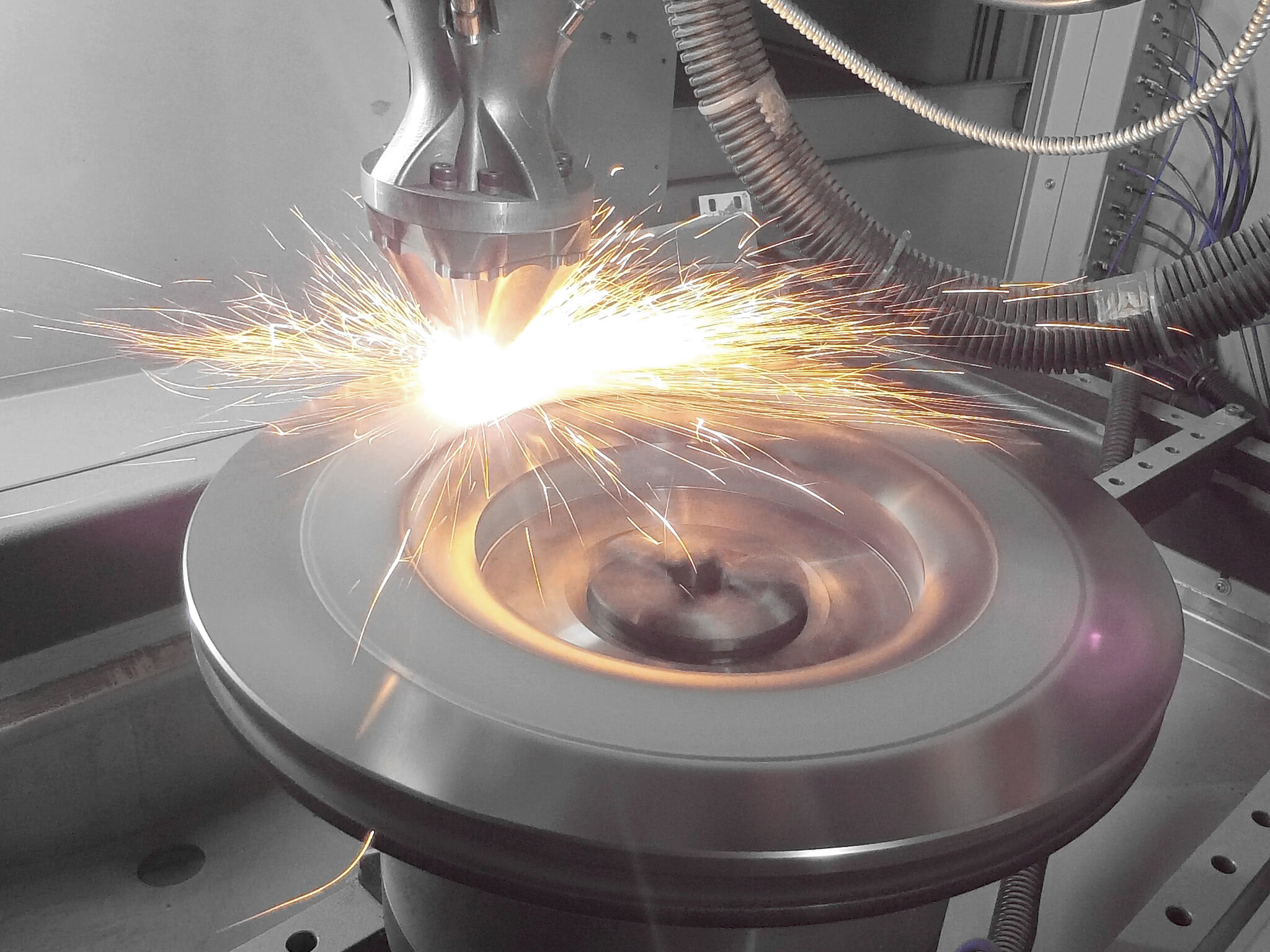

HIGH-SPEED LASER CLADDING

Achieve rapid and precise coating of brake discs, ensuring compliance with Euro 7 standards and reducing particulate emissions.

MODULAR SYSTEM DESIGN

Three configurations: RC-proto, RC-flex, and RC-fast, cater to various production needs, from prototyping to high-volume manufacturing.

FULLY AUTOMATED PRODUCTION

Integrate seamlessly into existing production lines with automated loading/unloading and real-time process monitoring.

PROPRIETARY TECHNOLOGY

In-house developed laser heads and nozzles ensure optimal energy efficiency and coating quality.

The RC Series by Prima Additive by Sodick is a comprehensive family of robotic systems engineered for the high-speed laser cladding of automotive brake discs. Specifically developed to meet the stringent demands of the Euro 7 regulation, these systems help car manufacturers reduce particulate emissions (PM10) by applying a uniform, wear-resistant coating on the surface of cast-iron brake discs.

This process, known as Rapid Coating, is based on laser metal deposition and ensures optimal coating performance with minimal material waste. Thanks to Prima Additive by Sodick’s extensive experience in advanced laser technologies, automation, and additive manufacturing, the RC Series provides unmatched process control, coating consistency, and integration flexibility.

The RC Series includes three modular solutions: RC-proto, RC-flex, and RC-fast, each designed to address specific production needs, from R&D and prototyping to high-volume, fully automated industrial lines. All configurations rely on robotic automation and are equipped with proprietary laser heads and cladding nozzles developed in-house to deliver best-in-class efficiency, coating precision, and uptime.

| Model | Description | Loading/Unloading | Laser Heads | Annual Output |

|---|---|---|---|---|

| RC-proto | Designed for prototyping and low-volume validation | Manual | 1 | Low |

| RC-flex | Flexible and scalable for mixed production | Automatic | 1 | Medium |

| RC-fast | High-throughput with dual laser heads | Automatic | 2 | High |

Each robotic cell can handle a variety of brake disc sizes, including those used in passenger cars and heavy-duty commercial vehicles. Fast changeovers, intelligent automation, and the ability to customize each setup make the RC Series the ideal solution for forward-looking OEMs and Tier 1 suppliers.

Already installed and operational in several leading European automotive facilities, the RC Series is a proven, scalable, and industry-ready platform for clean and compliant brake disc production.

Comprehensive production solutions

Beyond individual systems, Prima Additive by Sodick offers turnkey solutions encompassing the entire brake disc production process. From raw disc handling to coating, grinding, and quality control, our integrated lines are tailored to meet specific production volumes and requirements. Our commitment to continuous improvement ensures that our solutions evolve with industry needs, maintaining optimal performance and compliance.

For more information or to schedule a demonstration, please contact our sales team.

Why choose the RC Series for Brake Disc Laser Cladding

Turnkey automation

The RC Series is designed for seamless integration into existing manufacturing environments. Each system can be equipped with automated loading and unloading, two spindles to work in masked time, and real-time coordination between robots and laser systems. This reduces labor costs, maximizes uptime, and ensures consistent performance across shifts and product batches.

Full process control and monitoring

Our proprietary software integrates multiple sensors and monitoring tools into the production cell. Real-time data on meltpool temperature, layer thickness, and laser power ensure full traceability and allow for live quality control and predictive maintenance. All systems are ready for Industry 4.0 and can be connected to your MES or ERP system.

Centralized powder management

Powder storage, distribution, and recovery can be handled through a centralized system, enabling optimal material efficiency. Unused powder from the bonding layer is automatically collected, filtered, and reused, helping to reduce both cost and environmental impact.

Flexible and scalable configurations

RC-proto is ideal for laboratory use, testing new coating parameters or validating new disc designs. RC-flex provides a robust, scalable platform for mixed-volume production. RC-fast, with its dual-laser head setup, delivers maximum productivity in high-throughput industrial settings. Each system can be tailored to specific production needs.

In-house developed laser technology

Unlike other providers, Prima Additive by Sodick designs and manufactures its own laser cladding heads and nozzles. This guarantees full control over the deposition process and allows for rapid adaptation to new materials, geometries, or customer-specific requirements. The use of high-power fiber lasers (up to 22 kW) ensures rapid coating with minimal thermal deformation.

System integration and continuous improvement

The RC Series can be delivered as part of a complete, turnkey production line that includes grinding, handling, and post-processing. We collaborate directly with our customers to design and optimize every detail of the production flow, offering long-term support and continuous upgrades as new process innovations become available.

- Laser Power: up to 22 kW (16 kW standard)

- Disc Dimensions: Ø 250–500 mm

- Productivity: up to 1500 cm²/min (11–12 kg/h)

- Typical Layer Thickness: 100–350 µm

- Coating Materials: compatible with various metal powders, including steel (typically 430L, 316L) and composite materials (typically Ti or W carbides)

- Automation: options for manual or automatic loading/unloading

- Process Monitoring: real-time sensors for layer thickness and melt pool analysis

- Powder Management: centralized system with recovery and reuse capabilities

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Automation and digital factory integration

From Additive Manufacturing to Smart Factories: maximum efficiency with automation

Production scalability support

From Prototypes to Mass Production: Making AM Scalable & Industrially Viable

Global assistance and service

Reliable Additive Manufacturing support: anytime, anywhere

Ensuring the continuous operation and optimal performance of your additive manufacturing system is our priority.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Financial services for industry 4.0

Accelerate your investment in additive manufacturing

Investing in metal additive manufacturing is a strategic step toward efficiency, innovation, and competitiveness.

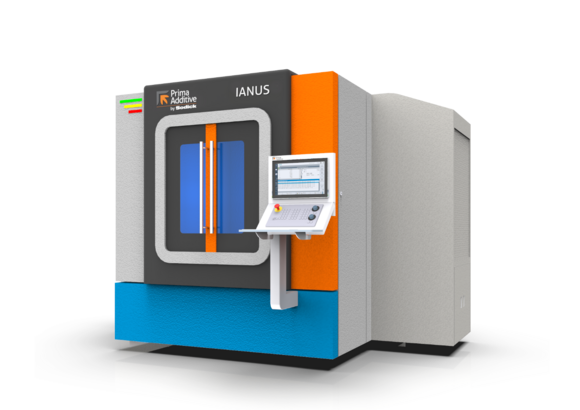

See other products and choose the best solution for your business

IANUS Cell

Direct Energy Deposition technology