Blue Laser Technology

Direct Energy Deposition Technology

Enhancing DED and Laser Welding technologies.

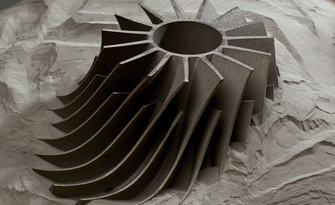

At Prima Additive by Sodick, we are constantly pushing the boundaries of laser technology to optimize metal-processing applications and advance additive manufacturing. One breakthrough innovation we worked on is the integration of blue industrial lasers into laser-based 3D metal printing methods, such as Direct Energy Deposition (DED).

Metals such as copper, aluminum, and gold have a remarkable ability to absorb blue light much better than infrared (IR) light. This inherent advantage, coupled with their high reflectivity in the IR spectrum, significantly enhances performance in metal processing. Initially, this advantage was leveraged in welding, where improved light absorption resulted in enhanced weld speed and superior part quality. Now, the blue laser is bringing these same benefits to additive manufacturing.

The blue laser enables the use of a lower-brightness laser to create a well-controlled melt pool while minimizing vaporization. Unlike IR printing, which is slow and struggles with print quality when dealing with highly reflective materials, the blue laser opens exciting applications in aerospace components, electric vehicle parts, batteries, and other highly specialized industries requiring to work copper or other reflective alloys.

At Prima Additive by Sodick, our solutions equipped with Direct Energy Deposition technology based on powder or wire can be seamlessly integrated with a blue laser. This integration allows for the deposition of highly reflective alloys, including copper, aluminum, gold, silver, and more, with unparalleled quality and precision.

We understand that different applications have varying requirements, which is why we offer a range of laser powers to choose from, spanning from 800 Watts to 4 kW. This flexibility ensures that you can select the ideal laser power to suit your specific needs.

The versatility of the blue laser extends to our IANUS cell, where it can be installed as a single laser source or in combination with another wavelength. This unique configuration empowers you to work alternately with two different wavelengths on the same system.

Consequently, you gain the ability to handle conventional alloys, reactive alloys, and highly reflective materials with exceptional quality and repeatability.

Managing and maintaining our blue lasers is as straightforward as handling common infrared lasers. The laser source possesses the same characteristics in terms of maintenance and usage, ensuring a seamless integration into your existing workflow.

With Prima Additive by Sodick's blue laser technology, you unlock a world of possibilities in metal processing and additive manufacturing. Experience enhanced performance, superior print quality, and the ability to work with highly reflective materials like never before.

See other products and choose the best solution for your business

IANUS Cell

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

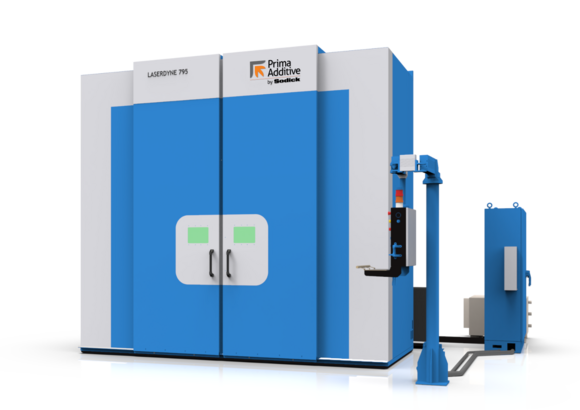

LASERDYNE® 795

Direct Energy Deposition technology

The medium scale, multi-axis deposition machine for 3D fabrication, repairing, cladding, and coating.

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

Laser Next 2141

Direct Energy Deposition technology

A large machine, available in various configurations, for repairing, coating, adding custom parts.

DED kit

Direct Energy Deposition Technology