DED Laser Head Configurations

DIRECT ENERGY DEPOSITION TECHNOLOGY

Three options for the best results.

Prima Additive by Sodick solutions for additive manufacturing with Direct Energy Deposition technology can be configured with three different laser heads developed with proprietary technologies.

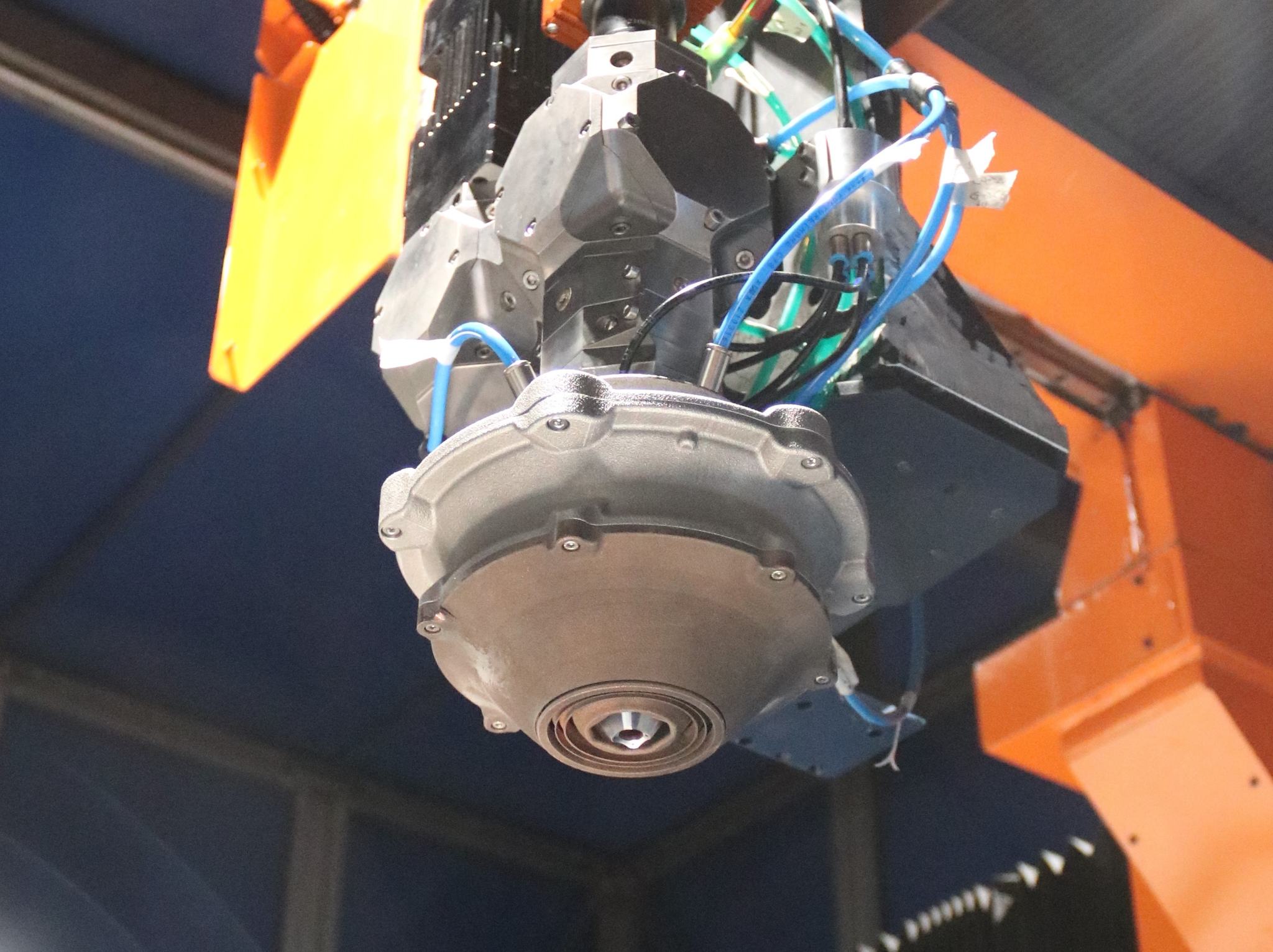

REAL_DED Head

The head designed for high productivity applications, allows to reach a deposition rate up to 100 cm3 / h. Inside it boasts a system patented by Prima Additive by Sodick that allows you to adjust the size of the laser beam in real-time. In this way, depending on the applications, precision or productivity can be preferred depending on the needs of the individual application or component area.

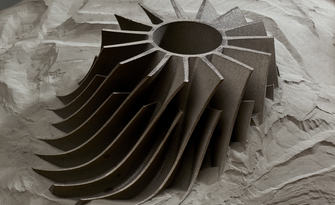

High Precision Configuration

Laser head equipped with a very high precision nozzle. Allows you to create walls as thin as 1 mm. With this configuration you will be able to create subtle features with which to customize components or to create large parts with very high precision and with an excellent surface quality, comparable to that obtainable using Powder Bed Fusion technology.

Inert Gas Shielding Nozzle

With this configuration it is possible to create an inert atmosphere around the deposition area. Thanks to the creation of a shielding gas around the molten puddle, highly reactive powders such as titanium or aluminum can be processed in total safety without the need to inertize the entire working chamber of the machine, thus making the processing of these materials easier and sustainable.

See other products and choose the best solution for your business

LASERDYNE® 795

Direct Energy Deposition technology

The medium scale, multi-axis deposition machine for 3D fabrication, repairing, cladding, and coating.

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

DED kit

Direct Energy Deposition Technology

Unleash the power of direct energy deposition technology.

Laser Next 2141

Direct Energy Deposition technology

A large machine, available in various configurations, for repairing, coating, adding custom parts.

IANUS Cell

Direct Energy Deposition technology