Print Sharp 250

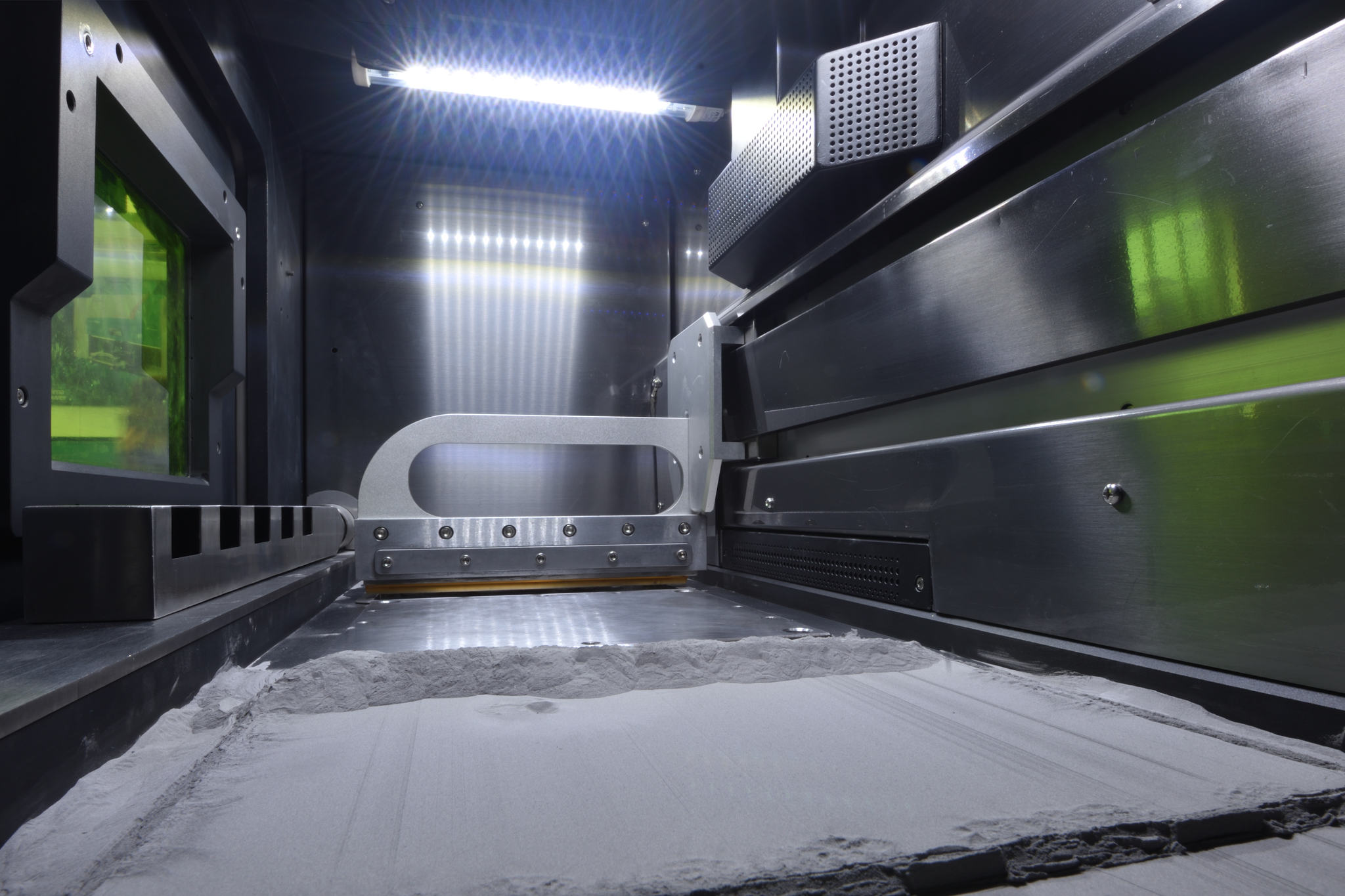

Powder Bed Fusion Technology

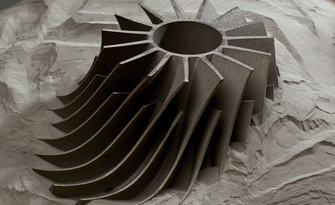

Great flexibility for any application in terms of size, materials, and complexity of parts that can be printed.

FLEXIBLE

Suitable for a wide range of materials, including reflective metals. An “open” system for configuring process and machine parameters.

RELIABLE

Capable of working continuously for up to 200 consecutive hours ensuring process repeatability and quality.

CONVENIENT

Excellent value for money together with an extensive network of suppliers of materials and consumables.

EASY TO USE

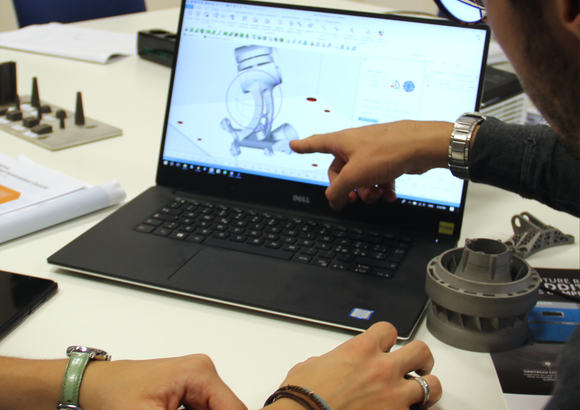

Simple operating process, intuitive software interface, easy maintenance and configuration.

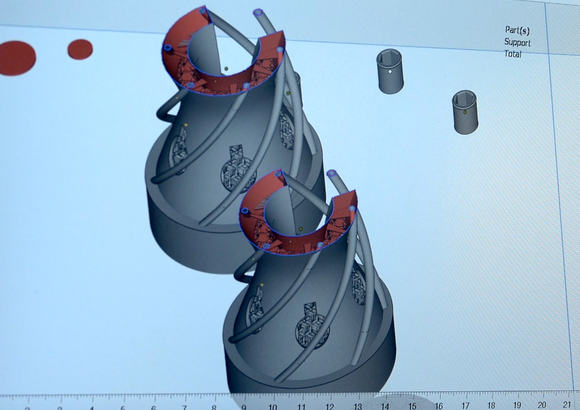

Print Sharp 250 is a medium-volume machine for Powder Bed Fusion applications, developed for industrial manufacturing of complex components. Suitable for both Additive Manufacturing companies and prototyping purposes, it offers high flexibility in terms of parts management and operational performance.

The competitive price of the entire system means that you can invest in Additive Manufacturing technology quickly and with little risk, intelligently achieving one of the most innovative manufacturing technologies available on the market.

Thanks to its modular configuration with easily removable components, a full material change can take place in less than 2 hours.

The machine comes with a “glove box” type access door to the working chamber, through which it is possible to move the powder inside the chamber while keeping the door closed during operations. The machine is also equipped with a socket for using an integrated vacuum cleaner directly inside the building chamber. This allows the operator to operate the machine safely, without coming into contact with the powder.

Print Sharp 250 includes intelligent control software designed to make operation easy and efficient, with an intuitive interface that makes setting up and operating the machine simple and hassle-free. The user can adjust parameters, modify printing conditions, change the building platform, material or powder collector. Intuitive operating procedures and simple maintenance operations increase the machine's utilisation rate and performance, helping you get the most out of your investment.

The Print Sharp 250 comes with a 500W single mode IR fibre laser.

Print Sharp 250 comes with a range of suggested configurations for each available material. Nevertheless, depending on the desired objective (output or quality), different sets of customised process parameters can be created to suit different applications.

Print Sharp 250 produces components with high quality mechanical and surface characteristics, and offers post-processing solutions to meet the most demanding objectives.

It has a filter unit for gas recirculation within the working area. The filter unit maintains a high level of cleanliness, minimising the need to replace parts prone to wear and tear.

- Building volume: 258x258x330

- Build rate: 12-30cm3/h (depending on material used and part geometry)

- Deposition layer height: 0.02 – 0.1mm

- Layer width: 0.1mm (single track width)

- Laser power: 500W single mode IR fibre laser

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Discover all the materials you can process with our PBF machines

Optimize your Prima Additive machine

Software for PBF

Software for Powder Bed Fusion technology

All the support you need to prepare files for producing additive manufacturing parts.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive by Sodick. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology