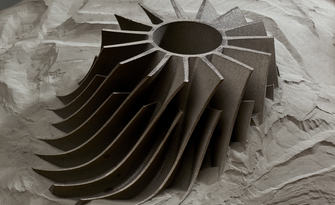

Building components from scratch with DED technology

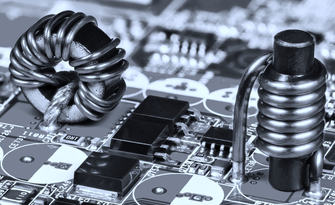

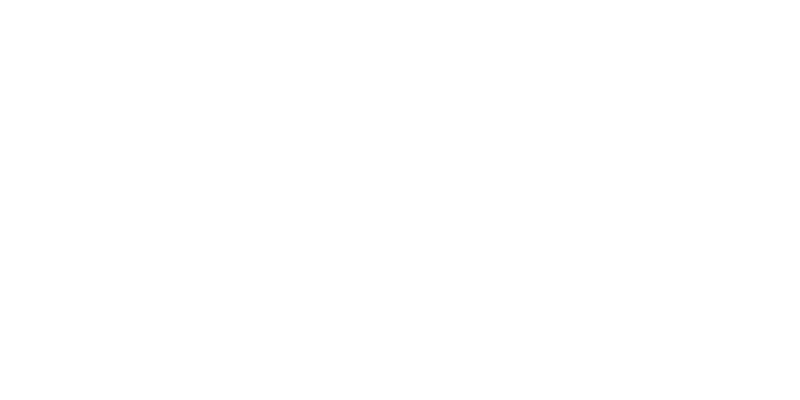

Thanks to Prima Additive's solutions it is possible to create large components using Direct Energy Deposition technology (also known as Directed Energy Deposition or Laser Metal Deposition).

Build large components in any material

We offer two different types of solutions: systems based on a robotic arm, such as our IANUS multiprocess cell, or five-axis, such as the LASERDYNE® 811 and 795 solutions, with which it is possible to print components within a workspace which can reach up to 2032 x 1016 x 1829 mm.

Usually, the working area of the machine is not inert, but when it comes to processing reactive materials, such as titanium or aluminum, it is possible to equip Prima Additive solutions with an inert chamber or with a gas shielding system around the laser head, which allows the creation of a localized inert atmosphere around the melt pool, thus eliminating the risks associated with the process.

Best-in-class quality

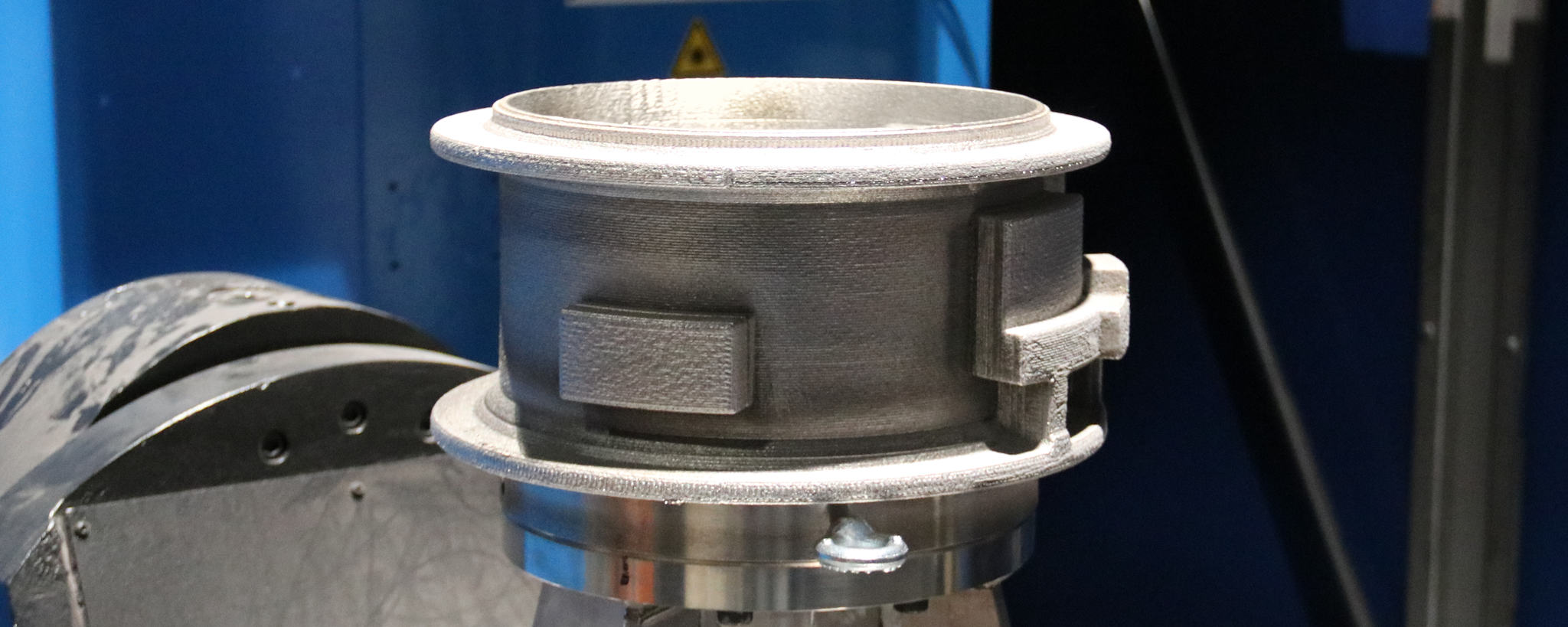

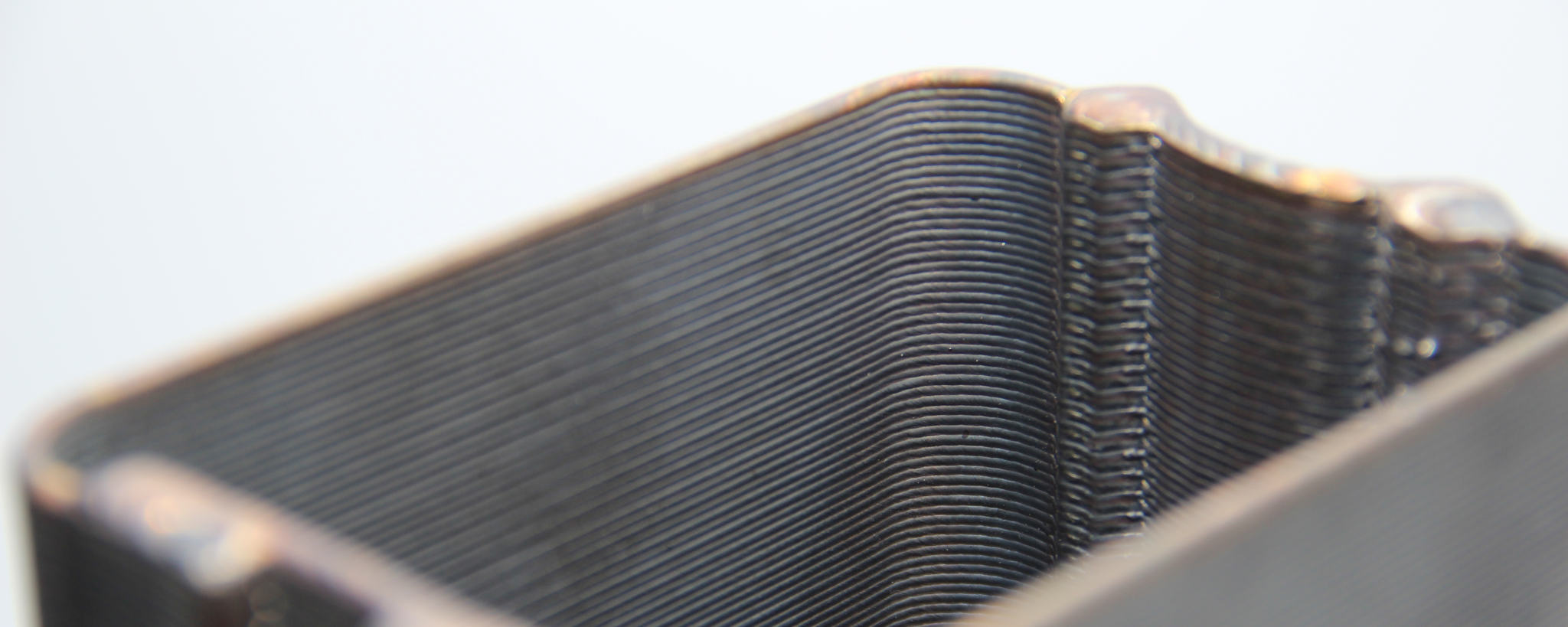

If you need to print components that require high surface quality or that require thin walls, we have developed a laser head nozzle configuration that allows you to create walls as thin as 1.2 mm, with a surface quality comparable to that achievable with Powder Bed Fusion technology.

Multi-material applications

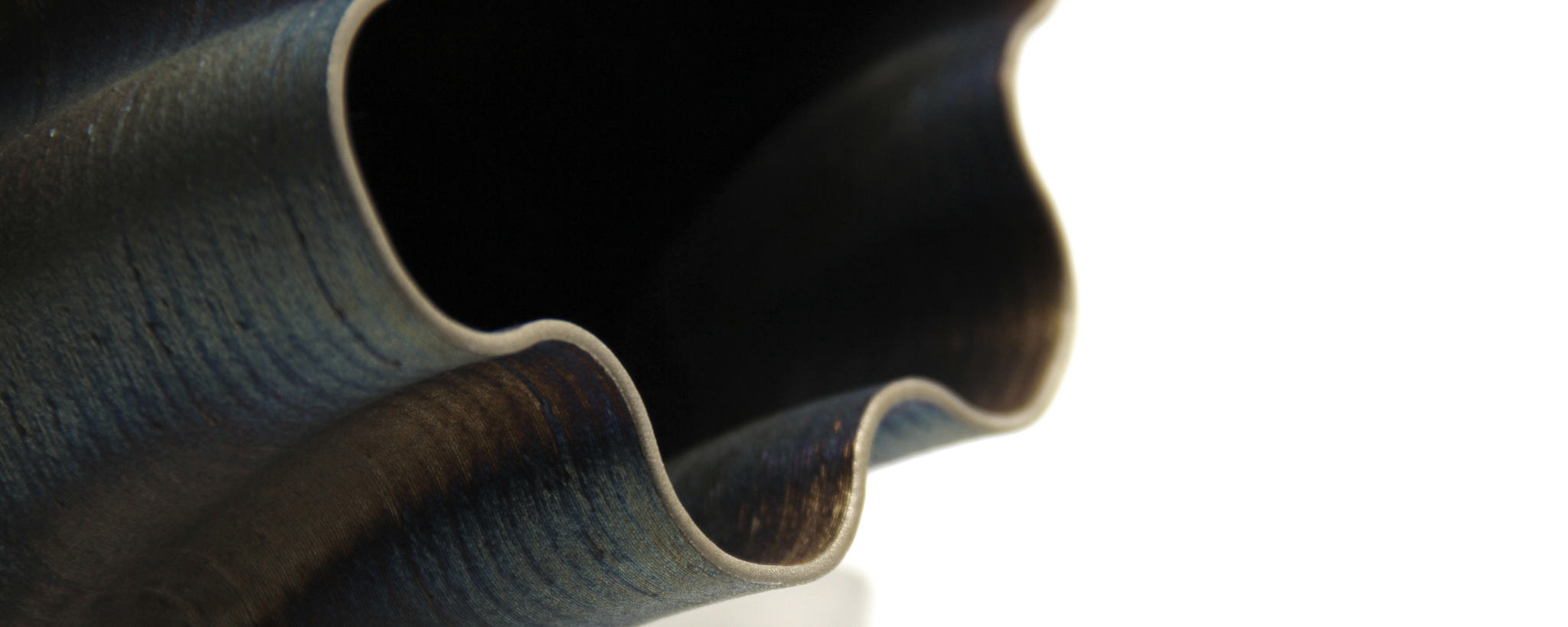

Furthermore, Direct Energy Deposition technology allows you to create multi-material applications thanks to the possibility of equipping the machine with a modular powder feeder with two separate powder hoppers that allow you to easily switch from one material to another in the same print job, but also to mix the two materials directly on the component.

To allow greater performance even on highly reflective materials such as pure copper or copper alloys, we also offer the possibility of installing the blue laser on our machines, which thanks to its short wavelength is particularly effective for processing these materials. Furthermore, in our IANUS multi-process robotic cell, it is possible to install two different laser sources, therefore having an infrared laser and a blue laser on the same machine, to alternatively use the most suitable one and create multi-material components even more effectively, for example, with some parts in Inconel and other parts in copper alloys, as required by various applications in the aerospace industry.

All the components made thanks to Prima Additive's Direct Energy Deposition solutions have exceptional mechanical properties: in fact, many companies regularly use components made from scratch thanks to this technology and have certified their parts for flight and space.

Not just powder: Wire DED

Prima Additive does not limit itself to offering Direct Energy Deposition solutions which involve the use of powder as starting material, but also offers solutions based on the use of metal wire, which proves to be particularly effective when it comes to building large components with high productivity.

Our options for DED technology

DED Laser Head Configurations

DIRECT ENERGY DEPOSITION TECHNOLOGY

Three options for the best results.

Blue Laser Technology

Direct Energy Deposition Technology

Enhancing DED and Laser Welding technologies.

Melting Pool Monitoring

Direct Energy Deposition technology

All controlled in real time

Take a look at Prima Additive's DED solutions

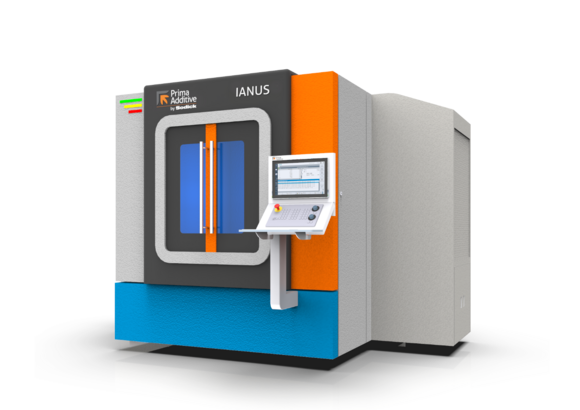

IANUS Cell

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

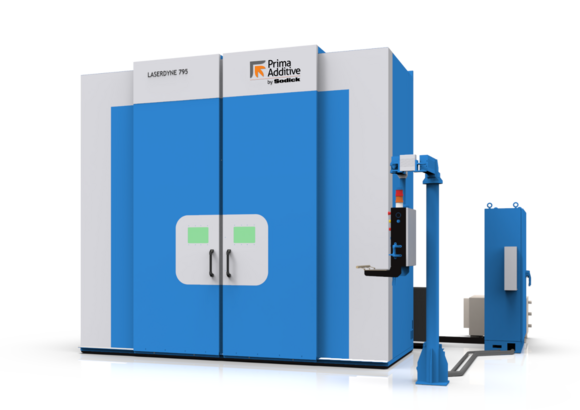

LASERDYNE® 795

Direct Energy Deposition technology