Additive Manufacturing Solutions

Metal Additive Manufacturing Laser Technologies

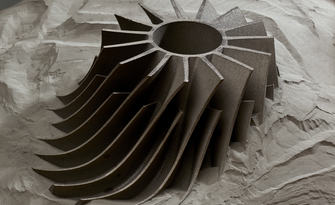

Metal Additive Manufacturing, also known as Metal 3D Printing, is a technology used to produce three-dimensional parts formed layer by layer by using a metal powder that is melted with a laser source.

Prima Additive develops and offers innovative laser systems for both major metal additive manufacturing processes: Powder Bed Fusion (PBF), also known as Selective Laser Melting (SLM), and Direct Energy Deposition (DED), also known as Laser Metal Deposition (LMD).

Powder Bed Fusion solutions

With Powder Bed Fusion technology, you can make objects having very complex geometries, with internal channels or very small parts, thus giving the finished piece a truly functional design.

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

300 Family

Powder Bed Fusion Technology

High productivity and precision for medium and big-sized components manufacturing.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Genius 400

Powder Bed Fusion Technology

Highly automated solution for large components up to 1 meter high.

Materials for Powder Bed Fusion

Aluminum alloys for PBF

Materials for Powder Bed Fusion

All the lightness of working with aluminum.

Steel alloys for PBF

Materials for Powder Bed Fusion

For quality that’s hard as steel.

Titanium alloys for PBF

Materials for Powder Bed Fusion

Lightness and biocompatibility all in one material.

Nickel alloys for PBF

Materials for Powder Bed Fusion

Endless strength, zero corrosion.

Cobalt Chrome alloys for PBF

Materials for Powder Bed Fusion

Biocompatible and durable.

Copper alloys for PBF

Materials for Powder Bed Fusion

The best electrical conductivity at your service.

Direct Energy Deposition solutions

With Direct Energy Deposition technology, also known as Laser Metal Deposition, you can choose to deposit metal powder exactly where it is needed. In this way, you can repair, customize or coat parts with high added value, reducing waste and embracing the Circular Economy model.

IANUS Cell

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

LASERDYNE® 795

Direct Energy Deposition technology

The medium scale, multi-axis deposition machine for 3D fabrication, repairing, cladding, and coating.

Materials for Direct Energy Deposition

Steel alloys for DED

Materials for Direct Energy Deposition

Superior hardness.

Titanium alloys for DED

Materials for Direct Energy Deposition

Light, Strong, Advanced.

Nickel alloys for DED

Materials for Direct Energy Deposition

For stress and corrosion resistant parts.

Cobalt Chrome alloys for DED

Materials for Direct Energy Deposition

Durability redefined.

Copper alloys for DED

Materials for Direct Energy Deposition

Excellent for conductivity.

Not just machines

Prima Additive also provides you with all the application support you need to reap the best possible benefits from the additive manufacturing process. Thanks to our experience, you can learn how to redesign your components to take full advantage of this technology: in so doing, you can produce more functional, lighter parts or integrate several components into one thanks to the freedom that additive technology brings.

Prima Additive opportunities for your industry.

How can additive manufacturing help you in your industry? There are many applications for metal 3D printing that can develop business in different areas: mechanics and machinery, universities and research, jewelry and design, naval, heat exchangers, electronics, injection molding, energy and oil & gas, automotive, aerospace, medical and dental.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Financial services for industry 4.0

Accelerate your investment in additive manufacturing

Investing in metal additive manufacturing is a strategic step toward efficiency, innovation, and competitiveness.

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

Prima Additive Product Range Brochure